Call us now : +8618401585304

HCVAC Car Parts Vacuum Metalizing Plant

60000 USD ($)/Set

Product Details:

- Product Type Coating Production Line

- Material Stainless Steel

- Type Industrial Coating Machine

- Computerized Yes

- Automatic Yes

- Control System PLC Control

- Humidification System Yes

- Click to View more

X

HCVAC Car Parts Vacuum Metalizing Plant Price And Quantity

- 60000 USD ($)/Set

- 1 Set

HCVAC Car Parts Vacuum Metalizing Plant Product Specifications

- Coating Production Line

- PLC Control

- Silver, Golden, Black, Rose Gold, Pink, Bronze, Coffee

- Yes

- Yes

- Stainless Steel

- Industrial Coating Machine

- One year warranty, lifetime maintenance

- Coating High Speed

- Yes

HCVAC Car Parts Vacuum Metalizing Plant Trade Information

- FOB SHENZHEN

- Letter of Credit (L/C) Telegraphic Transfer (T/T)

- 60 Days

- Contact us for information regarding our sample policy

- wooden package

- Eastern Europe Western Europe Middle East Africa Asia

- All India

- CE, ISO

Product Description

This machine is mainly used for plastic car parts to get a decorative coating, like chrome coating, alumnium coating, nickel coating etc. the coating is strong adhesion, shinning and smooth. There are different sizes for different prodcution capacity, machine is full automatic control, so easy to operate.

The coating experts of your own company: Full set solution for the coating production

HCVAC can help you to enter the PVD coating easily by our vacuum coating machine and full range service. We will provide with most suitable technology according to your requirements.

We will make the special coating solution for each customer; combine the full set production technics to meet your requirements, to ensure high efficiency of production.

We developed a complete after-sales system and effective service measures. Company now owns a professional after-sales service team with more than ten experienced engineers.

ISO 9001 standard to ensure the quality can meet the customers requirements.

Please send us your detailed requirements. We will provide the best solution for you!

This is evaporation-coated device in a vacuum chamber using electrical resistance heating, will close in the resistance wire on the metal wire (aluminum) vaporization melting, vaporization of the metal elements deposited on the substrate, but was Smooth high reflectivity of the coating to the surface of decorative items landscaping purposes.

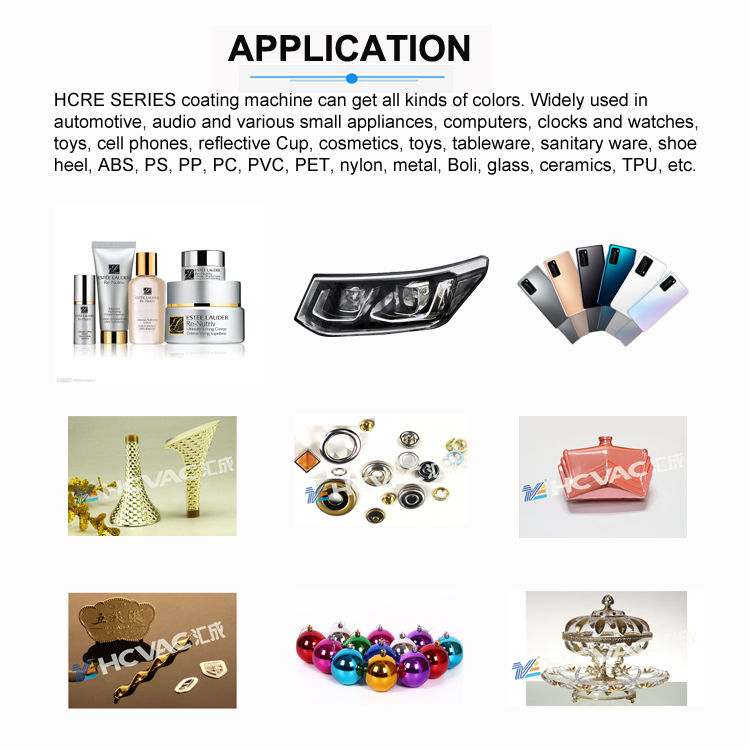

The equipment is: a reasonable structure, coating evenly into good-quality, pumping speed, the cycle of short, high efficiency and easy operation, low energy consumption and performance advantages of stability. Widely used in automotive, audio and various small appliances, computers, clocks and watches, toys, cell phones, reflective Cup, cosmetics, toys and other industries.

Machinable materials include: ABS, PS, PP, PC, PVC, nylon, metal, Boli, glass, ceramics, such as TPU.

Electroplating effects can include: general electroplating-face, dumb-(semi-mute, all dumb), the electroplating process wrinkles, lampworking, raindrops, seven color;

Coating color: gold, silver, red, blue, green, purple, seven color, and so on.

The company can design all based on user requirements specification models of Vacuum Coaters. Vacuum units and electric control system can be designed according to user requirements configuration.

Working Principle:

The whole process like vacuum pumping, plasma cleaning, Al film and the SiOx protective film coating, deflating etc. is all running fully automaticly.

Two doors (optional) with 6-axis (also 8 axis optional) rotation &revolution jig and evaporation motor. When handle the workpiece in one door. It can upload and unload the workpiece and install AL materials in another door at the same time. So the production performance is very excellent.

The aluminum deposition adopts resistance heating evaporation source, complex three-dimensional structure can also be uniform deposited.

SiOx protective film coating system is optional.

High performance is expected of today for automotive products whether they are used in racing environments or for everyday transportation. Performance, reliability, and service life must be optimized in order to meet the demands of the marketplace. Coatings for precision engine and drivetrain components can help meet the market demand by improving the engineering performance of the components. Wear-resistance, extended fatigue life, and corrosion-resistance can all be provided with coatings as long as the coating process does not degrade the bulk properties and dimensionality of the component. The low temperature automotive parts PVD coating machine process is designed specifically for these high performance applications.

The coating experts of your own company: Full set solution for the coating production

HCVAC can help you to enter the PVD coating easily by our vacuum coating machine and full range service. We will provide with most suitable technology according to your requirements.

We will make the special coating solution for each customer; combine the full set production technics to meet your requirements, to ensure high efficiency of production.

We developed a complete after-sales system and effective service measures. Company now owns a professional after-sales service team with more than ten experienced engineers.

ISO 9001 standard to ensure the quality can meet the customers requirements.

Please send us your detailed requirements. We will provide the best solution for you!

Specifications:

| Mode Dimension | JTZ-1214 | JTZ-1418 | JTZ-1619 | JTZ-1820 |

| 1200*1400mm | 1400*1800mm | 1600*1900mm | 1800*2000mm | |

| Film type | Meal film, translucent film, nonconductive film, electromagnetism shield film, dielectric film, etc. | |||

| Power source | Resistance evaporation power, DC magnetron power, RF power | |||

| Sputtering and electrode str ucture | Column magnetron targets, plane rectangle targets, twin targets, evaporation electrode. | |||

| Vacuum chamber structure | Vertical double door, Vertical single door, pump system postposition, horizontal single door, pump system for side. | |||

| Ultimate vacuum | 4.0*10-4pa | |||

| Vacuum system | Diffusion pump +Roots pump +Mechanical pump +Holding pump | |||

| Pump time | Pump from atmosphere to 8.5*10-3,15 minutes | |||

| Control mode | Manual/Automatic all in one mode, Touch screen + PLC | |||

FAQs of HCVAC Car Parts Vacuum Metalizing Plant:

Q: What is the warranty for HCVAC Car Parts Vacuum Metalizing Plant?

A: The plant comes with a one year warranty and lifetime maintenance.Q: Is the HCVAC Car Parts Vacuum Metalizing Plant automatic?

A: Yes, it is automatic.Q: What is the voltage requirement for the plant?

A: The voltage requirement is 380V.Q: What are the available colors for coating with this plant?

A: The available colors for coating are silver, golden, black, rose gold, pink, bronze, and coffee.Q: What is the power consumption of the plant?

A: The power consumption ranges from 45-90KW.Q: Is the control system of the plant computerized?

A: Yes, it is computerized with PLC control.Q: What is the material of construction for HCVAC Car Parts Vacuum Metalizing Plant?

A: The plant is made of stainless steel.Enter Buying Requirement Details

Send Inquiry

Send Inquiry