Call us now : +8618401585304

HCVAC Ceramic Cup and Plate Decorative Gold PVD Vacuum Ion Plating Machine

150000-500000 USD ($)/Set

Product Details:

- Product Type PVD Vacuum coating machine

- Material Stainless Steel

- Type Industrial Coating Machine Metal Coating Machine

- Coating Head Other

- Coating Material Other

- Computerized Yes

- Automatic Yes

- Click to View more

X

HCVAC Ceramic Cup and Plate Decorative Gold PVD Vacuum Ion Plating Machine Price And Quantity

- 1 Set

- 150000-500000 USD ($)/Set

HCVAC Ceramic Cup and Plate Decorative Gold PVD Vacuum Ion Plating Machine Product Specifications

- Coating Low Energy Consumption

- Yes

- Other

- Industrial Coating Machine Metal Coating Machine

- Stainless Steel

- PVD Vacuum coating machine

- One year warranty, lifetime maintenance

- PLC Control

- All colors

- Yes

- Other

HCVAC Ceramic Cup and Plate Decorative Gold PVD Vacuum Ion Plating Machine Trade Information

- FOB SHENZHEN

- Telegraphic Transfer (T/T) Letter of Credit (L/C)

- 60 Days

- Contact us for information regarding our sample policy

- Wooden Package or carton package

- Western Europe Eastern Europe Middle East Africa Asia

- All India

- CE, ISO

Product Description

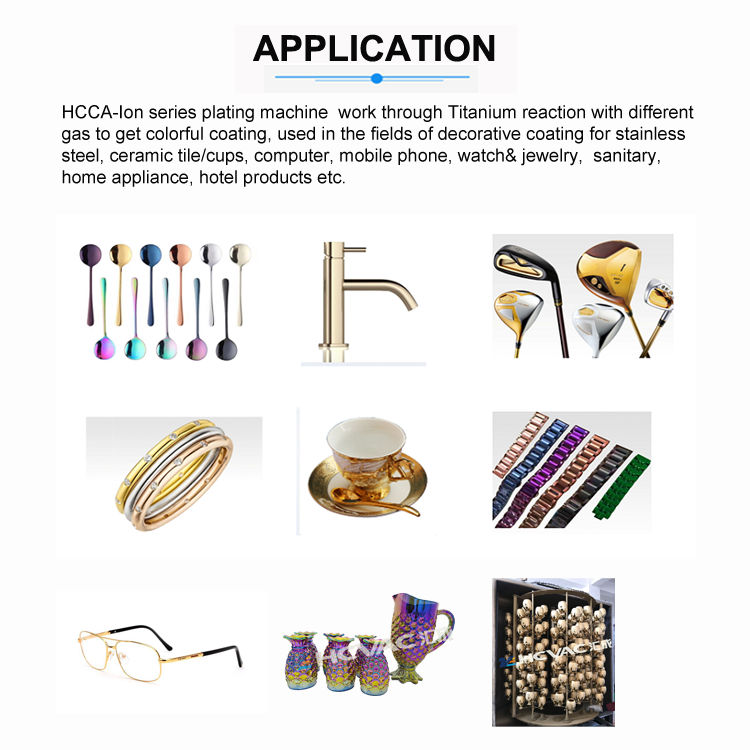

1. Brief intorduction:

can coat ceramic tiles, ceramic tableware, porcelain tiles, floor tiles, glass mosaic. Glass tiles. Beside ceramic, you can also coat metal, glass products. Until now we have make the biggest machine for coating tiles, its production ability is can coat 1500 square meter per day.

Ceramic ion coating machine is used to deposit TiN(gold color), Ti (silver color) and other coating on ceramic tiles. Thus it can replace the traditional paint gold, enhence the adhension, saves cost and improve production efficiency.

2. Detailed description:

Ceramic ion coating machine is a ion coating machine of efficiency, harmless and pollution-free. It has the features of fast deposition rate, great ionization rate, big ion energy, easy operation, low cost, large productive capacity, etc.

Characteristic: The principle of the electric arc is integrating cold cathode arc discharge self-sustained light unite pulse technique and magnetron sputtering technology, thinning the particles to improve the properties of the film. It can coat on the surface of the metal as well as nonmetal.

Applied industry: It can be used to coat metal film, titanium nitride, titanium carbide, and zirconium nitride, chromium nitride and titanium, nickel, chromium, copper, and other compounds film, multi-layer super-hard film, nitrogen-doped titanium film and the alloy film, and in a very short time to complete all the machining process, it is a highly efficient multi-functional coating equipment.

This machine is extensively used in the fields of ultra-hard coating about the tools and mould, decorative coating about car wheels, ceramics, golf, watches making, hotel product, sanitary ware, luminaires, optical frame, hardware, etc.

HCVAC can help you to enter the PVD coating easily by our vacuum coating machine and full range service. We will provide with most suitable technology according to your requirements.

We will make the special coating solution for each customer; Combine the full set production technics to meet your requirements, to ensure high efficiency of production.

Easy to implement

To many people unfamiliar with the process, PVD coating technology seems complicated. However, with the right investments and a good support, it is easier than expected. HCVAC has developed a turnkey coating process that makes a PVD coating centre easy to implement. A complete coating process consists of several steps: Stripping (depending on the parts history); Pre-treatment; Quality control; Cleaning & drying; Fixturing & visual inspection; PVD coating; Quality control & thickness measurement and post-treatment (depending on the application). These steps are all available from one partner: HCVAC Technology, including mature technics and coatings.

FAQs of HCVAC Ceramic Cup and Plate Decorative Gold PVD Vacuum Ion Plating Machine:

Q: What is the weight of the HCVAC Ceramic Cup and Plate Decorative Gold PVD Vacuum Ion Plating Machine?

A: The weight of the machine is 5-8 TON.Q: Is the machine computerized?

A: Yes, the machine is computerized.Q: What is the power consumption of the machine?

A: The power consumption ranges from 45-150KW.Q: What type of control system does the machine have?

A: The machine has a PLC control system.Q: What is the warranty for this machine?

A: The machine comes with a one year warranty and lifetime maintenance.Enter Buying Requirement Details

Send Inquiry

Send Inquiry Call Me Free

Call Me Free