Call us now : +8618401585304

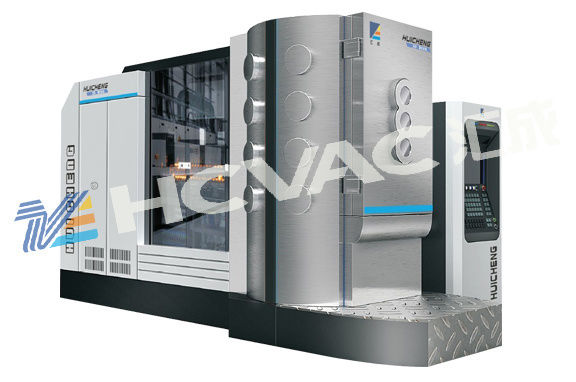

HCVAC MF Magnetron Sputtering Black PVD Vacuum Coating Machine

120000 USD ($)/Set

Product Details:

- Product Type PVD Vacuum coating machine

- General Use High-End Hardware and Stainless Steel Parts etc.

- Material Stainless Steel

- Type Industrial Coating Machine Metal Coating Machine

- Coating Head Other

- Coating Width costomized Centimeter (cm)

- Coating Material Other

- Click to View more

X

HCVAC MF Magnetron Sputtering Black PVD Vacuum Coating Machine Price And Quantity

- 120000 USD ($)/Set

- 1 Set

HCVAC MF Magnetron Sputtering Black PVD Vacuum Coating Machine Product Specifications

- Low Energy Consumption Coating High Speed

- 380V Volt (v)

- Industrial Coating Machine Metal Coating Machine

- Electric

- costomized Centimeter (cm)

- Yes

- Other

- Electric

- Electric

- High-End Hardware and Stainless Steel Parts etc.

- Yes

- 1 Year

- PLC Control

- Other

- Silver, Golden, Black, Rose Gold, Pink, Bronze

- PVD Vacuum coating machine

- Stainless Steel

HCVAC MF Magnetron Sputtering Black PVD Vacuum Coating Machine Trade Information

- Shenzhen, China

- Telegraphic Transfer (T/T) Letter of Credit (L/C)

- 60 Days

- Contact us for information regarding our sample policy

- Wooden cases

- Eastern Europe Western Europe Middle East Africa Australia North America South America Central America Asia

- All India

- CE, ISO

Product Description

HCVAC MF Magnetron Sputtering Black PVD Vacuum Coating Machine

This machine is used for steel parts to get IPG.IPS,IPR IPB, rose gold Platinum coatings etc. Its a environment protective equipment, no waste gas and no waste water, The main feature of Magnetron sputtering and arc vacuum coating machine for watch and jewelry is low cost , and adhesion of coating is stronger than tradition electroplating.

Usually for jewelry plating is using MF sputtering and DC sputtering coating machine. Middle frequency sputtering vacuum coating machine mainly integrate the technology of MF magnetron sputtering and electric arc ion evaporation coating, combining the ion source and the pulse bias voltage. It is fully automatic control when coating films.

Applied industry: MF magnetron sputtering black PVD coating machine can be used to coat metal film, titanium nitride, titanium carbide, and zirconium nitride, chromium nitride and titanium, nickel, chromium, copper, and other compounds film, multi-layer super-hard film, nitrogen-doped titanium film and the alloy film, and in a very short time to complete all the machining process, it is a highly efficient multi-functional coating equipment.

Films classified with colors:

- Real gold an real rosegold coating

- Imitation gold series: TiN, ZrN, TiN+Au, ZrN+Au

- Rose Gold Series: TiCN, TiAlN, TiCN+Au--Cu, TiAlN+Au, Cu

- Silver white series: CrN, CrSiN, Zr (micro N)

- Grey series: Ti, stainless steel (S.S), (S.S) N

- Coffee color series: TiCN, TiAlCN, ZrC

- Blue series: TiO, CrO, TiALN

- Black Series: TiC, TiC+iC, TiCN, TiAlN, TiAlCN, Ti (C, O) and DLC

Coating film performance:

- The coating is uniform, dense, with good adhesion, high hardness and low friction factor.

- The color does not fade over 2-3 years, which can meet the ROHS environmental standard.

- High physical property, good abrasion resistance; non-stick dirt on the surface of the coating.

- Stable performance, perspiration resistance/salt mist/abrasion/bend/RCA are all qualified.

We developed a complete after-sales system and effective service measures. Company now owns a professional after-sales service team with more than ten experienced engineers.

ISO 9001 standard to ensure the quality can meet the customers requirements

Why a HCVAC system?

- Over 3000 plants installed worldwide

- Quick cycle times

- High production capability with low energy consumption

- More up time due to ease of loading/unloading and low maintenance

- High productivity with only a single operator

- Steel process chambers, built to last

- Eco-friendly

- Space saving design

- PVD option available on all plants

- 1 year component warranty and 25 years minimum guaranteed working life

- Complete global network of consulting, engineering and renowned after sales service

Technical Specification

FAQs of HCVAC MF Magnetron Sputtering Black PVD Vacuum Coating Machine:

Q: What type of coating can this machine perform?

A: This machine can perform industrial coating and metal coating.Q: What is the power source for this machine?

A: The power source for this machine is electric.Q: What is the warranty period for this machine?

A: The warranty period for this machine is 1 year.Q: What is the material of construction for this machine?

A: This machine is made of stainless steel.Q: Can the coating width be customized?

A: Yes, the coating width is customizable.Enter Buying Requirement Details

Send Inquiry

Send Inquiry Call Me Free

Call Me Free