Call us now : +8618401585304

HCVAC PVD Coating Equipment System for Zinc Alloy Door Handle Furniture Knob Hardware

100000-300000 USD ($)/Set

Product Details:

- Product Type Coating Production Line

- Material Stainless Steel

- Type Industrial Coating Machine Metal Coating Machine

- Weight (kg) 5-8 Ton

- Coating Head Other

- Coating Material Other

- Computerized Yes

- Click to View more

X

HCVAC PVD Coating Equipment System for Zinc Alloy Door Handle Furniture Knob Hardware Price And Quantity

- 1 Set

- 100000-300000 USD ($)/Set

HCVAC PVD Coating Equipment System for Zinc Alloy Door Handle Furniture Knob Hardware Product Specifications

- One year warranty, lifetime maintenance

- 45-150KW

- Yes

- customized

- Gold, Silver, Rose Gold, Black, Blue and So on

- 380V

- Yes

- PLC Control

- 5-8 Ton

- Coating

- Electric

- Other

- Coating Production Line

- Industrial Coating Machine Metal Coating Machine

- Other

- Stainless Steel

HCVAC PVD Coating Equipment System for Zinc Alloy Door Handle Furniture Knob Hardware Trade Information

- FOB SHENZHEN

- Letter of Credit (L/C) Telegraphic Transfer (T/T)

- 60 Days

- Contact us for information regarding our sample policy

- Wooden Package or carton package

- Eastern Europe Western Europe Middle East Africa Asia

- All India

- CE, ISO

Product Description

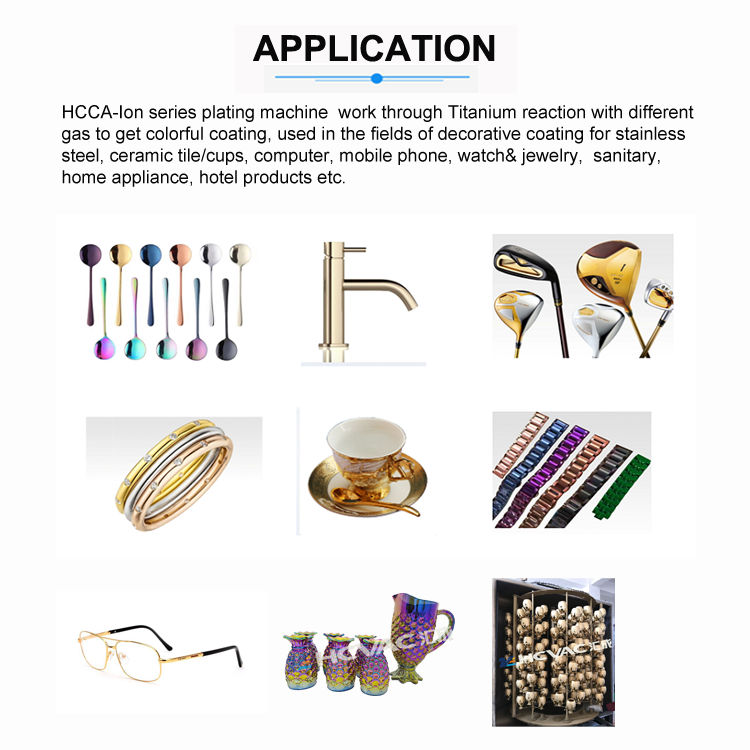

This machine is suitable for plating various hard metallic films and metallic compound films on the surface of metals and alloys having outstanding film quality, being widely applied to the surface treating area in such industries as high class decoration, watch, glasses, cutting tool and hardware.

HCVAC decorative PVD films are routinely used as a replacement for electroplated chrome. They can be applied directly over almost any substrate material and can be deposited in a wide variety of colors. The process parameters to deposit each color are stored in software recipes with different process steps. Once the coating process has started, all of the relevant process parameters are continuously monitored and controlled by the on-board computer software.

Applied industry: It is widely used in the furniture accessories, hotel products, sanitary ware, watch and jewelries, mobile shell, hardware, tableware, etc. It can coat TiN, TiC, TiCN, TiAlN, CrN, Cu, Au, Al2O3and other decorative films. It can get fineness and smooth film, good adhesion.

The color can be gold, silver, rosegold, blue, copper, bronze, black, more fineness, more uniform coating than galvanization.

Films classified with colors:

Real gold an real rosegold coating

Imitation gold series: TiN, ZrN, TiN+Au, ZrN+Au

Rose Gold Series: TiCN, TiAlN, TiCN+Au--Cu, TiAlN+Au, Cu

Silver white series: CrN, CrSiN, Zr (micro N)

Grey series: Ti, stainless steel (S.S), (S.S) N

Coffee color series: TiCN, TiAlCN, ZrC

Blue series: TiO, CrO, TiALN

Black Series: TiC, TiC+iC, TiCN, TiAlN, TiAlCN, Ti (C, O) and DLC

Coating film performance:

(1) The coating is uniform, dense, with good adhesion, high hardness and low friction factor.

(2) The color does not fade over 2-3 years, which can meet the ROHS environmental standard.

(3) High physical property, good abrasion resistance; non-stick dirt on the surface of the coating.

(4) Stable performance, perspiration resistance/salt mist/abrasion/bend/RCA are all qualified.

The coating experts of your own company: Full set solution for the coating production

Specifications:

FAQs of HCVAC PVD Coating Equipment System for Zinc Alloy Door Handle Furniture Knob Hardware:

Q: What type of coating can this equipment system provide?

A: This equipment system provides industrial coating for metal surfaces such as zinc alloy door handles, furniture knobs, and hardware.Q: Is the HCVAC PVD Coating Equipment System computerized?

A: Yes, the equipment system is computerized and features PLC control for precise and efficient operation.Q: What is the power source for this equipment system?

A: The power source for this equipment system is electric, with a voltage requirement of 380V and power consumption ranging from 45-150KW.Q: What are the available colors for coating with this equipment system?

A: The available colors for coating include gold, silver, rose gold, black, blue, and more.Q: What is the warranty for the HCVAC PVD Coating Equipment System?

A: The equipment system comes with a one year warranty and lifetime maintenance support.Enter Buying Requirement Details

Send Inquiry

Send Inquiry Call Me Free

Call Me Free