Call us now : +8618401585304

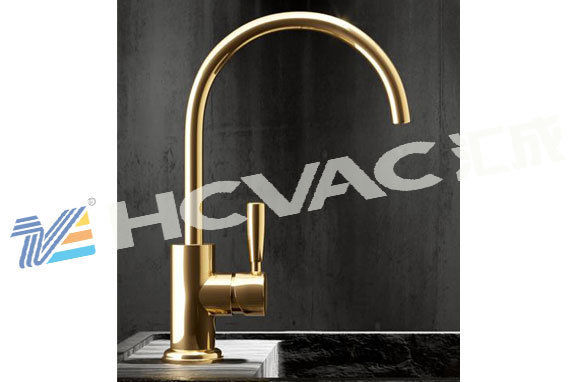

HCVAC PVD Gold Coating Machine Plant for Kitchen Faucet Bathroom Fitting

150000-500000 USD ($)/Set

Product Details:

- Product Type PVD Vacuum coating machine

- Material Stainless Steel

- Type Industrial Coating Machine Metal Coating Machine

- Weight (kg) 5-8 Ton

- Coating Head Other

- Coating Material Other

- Computerized Yes

- Click to View more

X

HCVAC PVD Gold Coating Machine Plant for Kitchen Faucet Bathroom Fitting Price And Quantity

- 1 Set

- 150000-500000 USD ($)/Set

HCVAC PVD Gold Coating Machine Plant for Kitchen Faucet Bathroom Fitting Product Specifications

- Yes

- customized

- Yes

- 380V

- Coating

- Other

- 45-150KW

- Other

- Industrial Coating Machine Metal Coating Machine

- Stainless Steel

- PLC Control

- 5-8 Ton

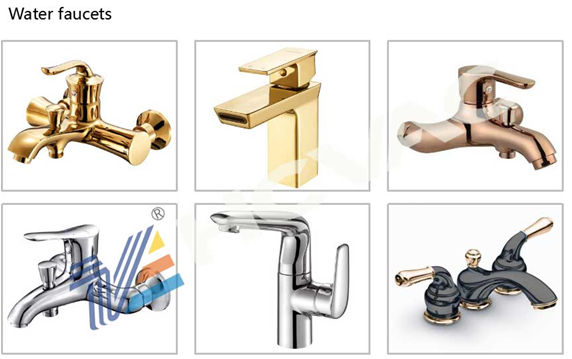

- Silver, Golden, Black, Rose Gold, Pink, Bronze, Coffee

- PVD Vacuum coating machine

- One year warranty, lifetime maintenance

HCVAC PVD Gold Coating Machine Plant for Kitchen Faucet Bathroom Fitting Trade Information

- FOB SHENZHEN

- Letter of Credit (L/C) Telegraphic Transfer (T/T)

- 60 Days

- Contact us for information regarding our sample policy

- Wooden Package or carton package

- Eastern Europe Western Europe Africa Middle East Asia

- All India

- CE, ISO

Product Description

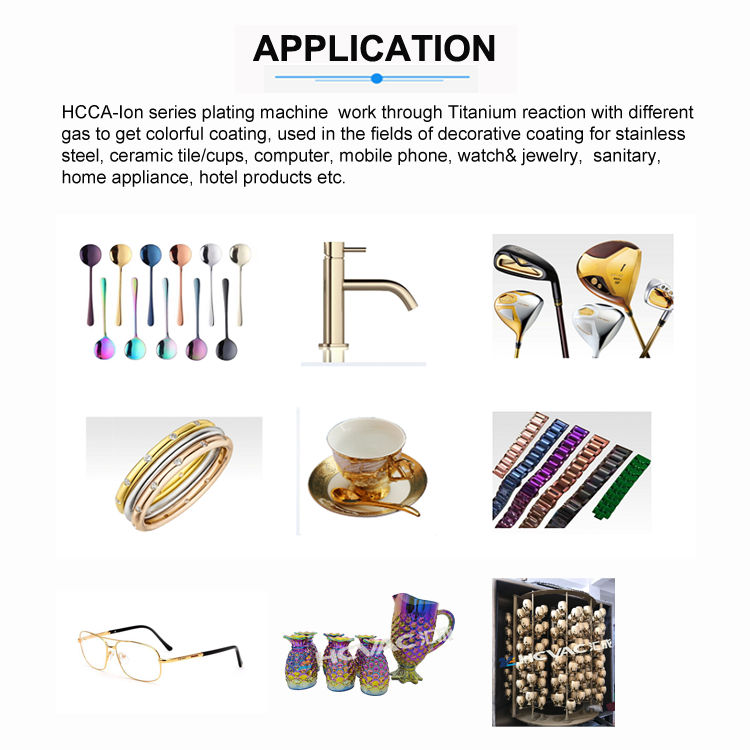

The machine is mainly design for sanitary ware/bathroom fitting parts. Its equipped with several big size electrical arc evaporation sources and magnetron sputtering coating system, to deposit high performance metal decorative film on brass, zinc alloy, stainless steel, plastic and other metal parts surface. It can get all types of metal color series on substrate. The coating film includes TiN, Zr,T iCN, ZrCN, CrN, CrCN, brass, bronze, chrome etc. Color series includes AF, SN, BN, VF, BV, G, BX, TB, AF, SN, 96CB, CB, TXB, VS, S, BS, BRZ, BGD, PGD and so on. It can get different colors by adjusting coating technics. It is largely used in the sanitary ware/ Kitchen ware field.

HCVAC decorative PVD films are routinely used as a replacement for electroplated chrome. They can be applied directly over almost any substrate material and can be deposited in a wide variety of colors. The process parameters to deposit each color are stored in software recipes with different process steps. Once the coating process has started, all of the relevant process parameters are continuously monitored and controlled by the on-board computer software.

Over 3000 plants installed worldwide

Quick cycle times

High production capability with low energy consumption

More up time due to ease of loading/unloading and low maintenance

High productivity with only a single operator

Steel process chambers, built to last

Eco-friendly

Space saving design

PVD option available on all plants

1 year component warranty and 25 years minimum guaranteed working life

Complete global network of consulting, engineering and renowned after sales service

HCVAC

We will make the full set special coating solution for each customer; combine the full set production technics to meet your requirements, to ensure high efficiency of production.

ISO 9001 standard to ensure the quality can meet the customers requirements.

Easy to implement

To many people unfamiliar with the process, PVD coating technology seems complicated. However, with the right investments and a good support, it is easier than expected. HCVAC has developed a turnkey coating process that makes a PVD coating centre easy to implement. A complete coating process consists of several steps: Stripping (depending on the parts history); Pre-treatment; Quality control; Cleaning & drying; Fixturing & visual inspection; PVD coating; Quality control & thickness measurement and post-treatment (depending on the application). These steps are all available from one partner: HCVAC Technology, including mature technics and coatings.

FAQs of HCVAC PVD Gold Coating Machine Plant for Kitchen Faucet Bathroom Fitting:

Q: What is the power consumption of HCVAC PVD Gold Coating Machine Plant?

A: The power consumption of HCVAC PVD Gold Coating Machine Plant is 45-150KW.Q: What is the warranty of the product?

A: The product comes with a one year warranty and lifetime maintenance.Q: Is the HCVAC PVD Gold Coating Machine Plant computerized and automatic?

A: Yes, it is computerized and automatic.Q: What is the material of the machine?

A: The machine is made of stainless steel.Q: What are the available colors for the coating?

A: The available colors for the coating are silver, golden, black, rose gold, pink, bronze, and coffee.Enter Buying Requirement Details

Send Inquiry

Send Inquiry Call Me Free

Call Me Free