Call us now : +8618401585304

HCVAC PVD Vacuum Coating Machine for Stainless Steel, Ceramic, Glass, Plastic

150000 USD ($)/Set

Product Details:

- Product Type Coating Production Line

- General Use Surface vacuum coating for watch&clock, jewelries, tools, plastic, stainless steel sheet etc.

- Material Stainless Steel

- Type Metal Coating Machine Industrial Coating Machine

- Coating Material Other

- Computerized Yes

- Automatic Yes

- Click to View more

X

HCVAC PVD Vacuum Coating Machine for Stainless Steel, Ceramic, Glass, Plastic Price And Quantity

- 150000.00 - 500000.00 USD ($)/Set

- 150000 USD ($)/Set

- 1 Set

HCVAC PVD Vacuum Coating Machine for Stainless Steel, Ceramic, Glass, Plastic Product Specifications

- Electric

- One year warranty, lifetime maintenance

- Stainless Steel

- PLC Control

- Electric

- Yes

- Surface vacuum coating for watch&clock, jewelries, tools, plastic, stainless steel sheet etc.

- Coating Low Energy Consumption

- Yes

- Other

- Metal Coating Machine Industrial Coating Machine

- Coating Production Line

- Gold, Rosegold, Silver, Black, Blue, Rainbow Ect

HCVAC PVD Vacuum Coating Machine for Stainless Steel, Ceramic, Glass, Plastic Trade Information

- Shenzhen, China

- Letter of Credit (L/C) Telegraphic Transfer (T/T)

- 60 Days

- Wooden Package

- Western Europe Eastern Europe Middle East North America Central America Australia South America Asia Africa

- All India

- CE, ISO

Product Description

HCVAC PVD Vacuum Coating Machine for Stainless Steel, Ceramic, Glass, Plastic

PVD, short for physical vapor deposition, is the technology to deposit thin film by evaporating or sputtering the material under the vacuum conditions. A vacuum chamber is necessary to avoid reaction of the vaporized material with air. PVD coating is used to provide new, additional value and features to the product, such as vivid color, abrasion resistance and reduced friction coatings. In general, HCVAC is specialized in PVD coatings.

HCVAC manufactures and supplies all kinds of PVD vacuum coating machines. Now it is a market leader in the high-vacuum treatment field with customers from all around the world. Huicheng produces a complete range of machinery, offering different types of processes: high vacuum evaporation, multi-arc, DC sputtering, MF magnetron sputtering, continuous magnetron sputtering line etc.

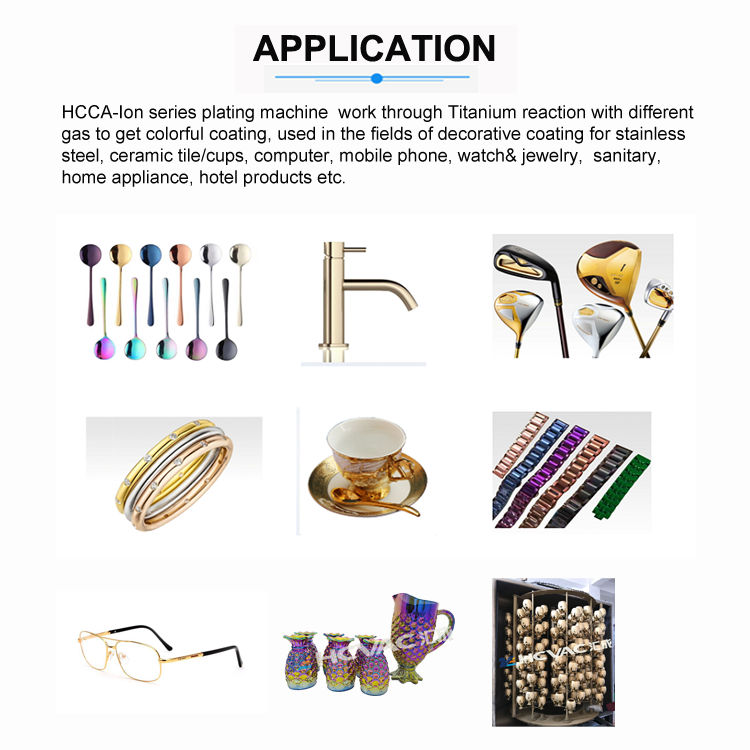

Applied industries:

Surface vacuum coating for watch&clock, jewelries, tools, plastic, stainless steel sheet etc.

HCVAC decorative PVD films are routinely used as a replacement for electroplated chrome. They can be applied directly over almost any substrate material and can be deposited in a wide variety of colors. The process parameters to deposit each color are stored in software recipes with different process steps. Once the coating process has started, all of the relevant process parameters are continuously monitored and controlled by the on-board computer software.

FAQs of HCVAC PVD Vacuum Coating Machine for Stainless Steel, Ceramic, Glass, Plastic:

Q: What is the power consumption of HCVAC PVD Vacuum Coating Machine?

A: The power consumption of HCVAC PVD Vacuum Coating Machine is 45-150KW.Q: What is the general use of this coating machine?

A: The general use of this coating machine is for surface vacuum coating for watch&clock, jewelries, tools, plastic, stainless steel sheet etc.Q: What type of control system does this machine have?

A: This machine has a PLC control system.Q: What is the warranty for HCVAC PVD Vacuum Coating Machine?

A: The warranty for this machine is one year with lifetime maintenance.Q: What material is used for making this coating machine?

A: The coating machine is made of stainless steel.Q: Is this coating machine computerized?

A: Yes, this coating machine is computerized.Q: What is the voltage requirement for this coating machine?

A: The voltage requirement for this coating machine is 380V.Enter Buying Requirement Details

Send Inquiry

Send Inquiry Call Me Free

Call Me Free