Call us now : +8618401585304

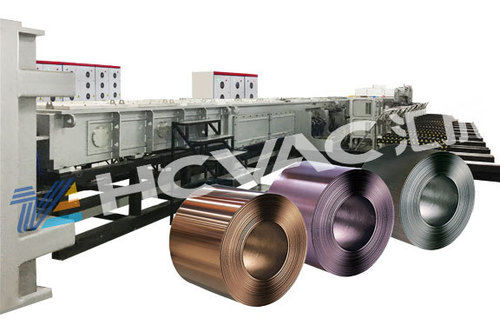

HCVAC PVD Vacuum Coating System for Stainless Steel Coil Sheet Metal Strip

400000-5000000 USD ($)/Set

Product Details:

- Product Type PVD Vacuum coating machine

- General Use Applied for the glass and flexible substrate used for display, touch panel, optical coating and OGS key parts and process. Satisfy the requirements of the cell phone, tablet, laptop and large-area TV.

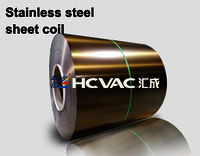

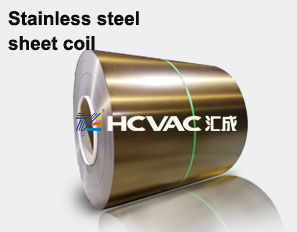

- Material Stainless Steel

- Type Industrial Coating Machine Metal Coating Machine

- Weight (kg) 10-30 Ton

- Coating Speed 0.01~6.00m/min m/m

- Computerized Yes

- Click to View more

X

HCVAC PVD Vacuum Coating System for Stainless Steel Coil Sheet Metal Strip Price And Quantity

- 400000-5000000 USD ($)/Set

- 1 Container

HCVAC PVD Vacuum Coating System for Stainless Steel Coil Sheet Metal Strip Product Specifications

- Electric

- 10-30 Ton

- One year warranty, lifetime maintenance

- 380V Volt (v)

- 0.01~6.00m/min m/m

- Yes

- customized

- PLC Control

- Applied for the glass and flexible substrate used for display, touch panel, optical coating and OGS key parts and process. Satisfy the requirements of the cell phone, tablet, laptop and large-area TV.

- Yes

- Industrial Coating Machine Metal Coating Machine

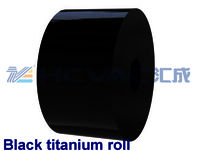

- Gold, Silver, Rose Gold, Black, Blue and So on

- 120-500KW

- Stainless Steel

- Coating High Speed

- PVD Vacuum coating machine

HCVAC PVD Vacuum Coating System for Stainless Steel Coil Sheet Metal Strip Trade Information

- FOB SHENZHEN

- Telegraphic Transfer (T/T) Letter of Credit (L/C)

- 60 Days

- Wooden Package or carton package

- Western Europe Eastern Europe Africa Middle East Asia

- All India

- CE, ISO

Product Description

The HCMRC series is a modular sputter web coating system. Every function (unwinding, processing of front-side, rewinding) is installed in a separate vacuum module. Its designed for sputter coating of flexible materials in a roll to roll vacuum process.

Applications:

Touch panel and optical coating:

- Applied for the glass and flexible substrate used for display, touch panel, optical coating and OGS key parts and process.

- Satisfy the requirements of the cell phone, tablet, laptop and large-area TV.

- Anti-reflection (AR coating): 2AR, 4AR, 6AR

- Index matching+ITO(IMITO)

- SiO2+ITO film

- Mo/Al/Mo film

- ITO film

-

Solar Cell

- Delivered 3GW a-si PVD

- CIGS: Mo, CuGa, In, AZO, ZnO

- a-Si/u-Si: Al, ZO,Ag, NiCr

- HIT: ITO,Ag, Cu

Gereral Specification

Company Introduction:

The coating experts of your own company: Full set solution for the coating production

HCVAC can help you to enter the PVD coating easily by our vacuum coating machine and full range service. We will provide with most suitable technology according to your requirements.

We will make the special coating solution for each customer; combine the full set production technics to meet your requirements, to ensure high efficiency of production.

Easy to implement

To many people unfamiliar with the process, PVD coating technology seems complicated. However, with the right investments and a good support, it is easier than expected. HCVAC has developed a turnkey coating process that makes a PVD coating centre easy to implement. A complete coating process consists of several steps: stripping (depending on the parts history); pre-treatment; quality control; cleaning & drying; fixturing & visual inspection; PVD coating; quality control & thickness measurement and post-treatment (depending on the application). These steps are all available from one partner: HCVAC Technology, including mature technics and coatings.

We developed a complete after-sales system and effective service measures. Company now owns a professional after-sales service team with more than ten experienced engineers.

ISO 9001 standard to ensure the quality can meet the customers requirements

Applications:

Touch panel and optical coating:

- Applied for the glass and flexible substrate used for display, touch panel, optical coating and OGS key parts and process.

- Satisfy the requirements of the cell phone, tablet, laptop and large-area TV.

- Anti-reflection (AR coating): 2AR, 4AR, 6AR

- Index matching+ITO(IMITO)

- SiO2+ITO film

- Mo/Al/Mo film

- ITO film

-

Solar Cell

- Delivered 3GW a-si PVD

- CIGS: Mo, CuGa, In, AZO, ZnO

- a-Si/u-Si: Al, ZO,Ag, NiCr

- HIT: ITO,Ag, Cu

Gereral Specification

Company Introduction:

The coating experts of your own company: Full set solution for the coating production

HCVAC can help you to enter the PVD coating easily by our vacuum coating machine and full range service. We will provide with most suitable technology according to your requirements.

We will make the special coating solution for each customer; combine the full set production technics to meet your requirements, to ensure high efficiency of production.

Easy to implement

To many people unfamiliar with the process, PVD coating technology seems complicated. However, with the right investments and a good support, it is easier than expected. HCVAC has developed a turnkey coating process that makes a PVD coating centre easy to implement. A complete coating process consists of several steps: stripping (depending on the parts history); pre-treatment; quality control; cleaning & drying; fixturing & visual inspection; PVD coating; quality control & thickness measurement and post-treatment (depending on the application). These steps are all available from one partner: HCVAC Technology, including mature technics and coatings.

We developed a complete after-sales system and effective service measures. Company now owns a professional after-sales service team with more than ten experienced engineers.

ISO 9001 standard to ensure the quality can meet the customers requirements

FAQs of HCVAC PVD Vacuum Coating System for Stainless Steel Coil Sheet Metal Strip:

Q: What is the control system of HCVAC PVD Vacuum Coating System for Stainless Steel Coil Sheet Metal Strip?

A: The control system is PLC Control, which offers automatic operation.Q: What are the available colors for coating with this system?

A: The available colors for coating are Gold, Silver, Rose Gold, Black, Blue, and more.Q: What is the general use of this coating system?

A: It is applied for the glass and flexible substrate used for display, touch panel, optical coating, and OGS key parts and process. It satisfies the requirements of the cell phone, tablet, laptop, and large-area TV.Q: What is the warranty for this product?

A: The product comes with a one-year warranty and lifetime maintenance.Q: What is the power consumption of this coating system?

A: The power consumption ranges from 120-500KW.Enter Buying Requirement Details

Send Inquiry

Send Inquiry