Call us now : +8618401585304

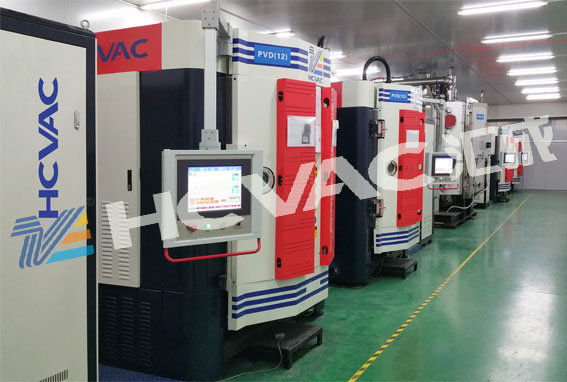

HCVAC Stainless Steel Flatware Pvd Titanium Coating Machine Vacuum Chamber

100000-500000 USD ($)/Set

Product Details:

- Product Type PVD Vacuum coating machine

- Material Stainless Steel

- Type Industrial Coating Machine Metal Coating Machine

- Weight (kg) 5-8 Tonne

- Computerized Yes

- Automatic Yes

- Control System PLC Control

- Click to View more

X

HCVAC Stainless Steel Flatware Pvd Titanium Coating Machine Vacuum Chamber Price And Quantity

- 1 Set

- 100000-500000 USD ($)/Set

HCVAC Stainless Steel Flatware Pvd Titanium Coating Machine Vacuum Chamber Product Specifications

- Silver, Golden, Black, Rose Gold, Pink, Bronze, Coffee

- PVD Vacuum coating machine

- Yes

- 45-150KW

- Yes

- Industrial Coating Machine Metal Coating Machine

- Coating

- One year warranty, lifetime maintenance

- 5-8 Tonne

- Stainless Steel

- customized

- PLC Control

- 380V

HCVAC Stainless Steel Flatware Pvd Titanium Coating Machine Vacuum Chamber Trade Information

- FOB SHENZHEN

- Letter of Credit (L/C) Telegraphic Transfer (T/T)

- 60 Days

- Contact us for information regarding our sample policy

- Wooden Package or carton package

- Eastern Europe Western Europe Middle East Asia Africa

- All India

- CE, ISO

Product Description

HCVAC Stainless Steel Flatware Pvd Titanium Coating Machine Vacuum Chamber

This machine mainly integrate the technology of arc ion evaporation, combining the ion source and the pulse bias voltage. It is full automation control when coating films. The coating will be good adhesion, scratch-proof.

The principle of vacuum electric arc ion coating is based on cold cathode, self-sustained arc discharge plasma evaporation, ionization material, combine pulsed bias technical to improve the energy and activity of deposited particles, and enhance the properties of coating. It can deposit coatings on the surface of metal as well as non-metal.

Applied industries:

It can be used to coat metal film, titanium nitride, titanium carbide, and zirconium nitride, chromium nitride and titanium, nickel, chromium, copper , and other compounds film, multi-layer super-hard film, nitrogen-doped titanium film and the alloy film ( TiN, TiC, TiCN, TiAlN, CrN, Cu, Au, Al2O3and other decorative films etc.) and in a very short time to complete all the machining process, it is a highly efficient multi-functional coating equipment.

This machine is extensively used in the fields of decorative coating for stainless steel, ceramic tile/cups, computer, mobile phone, watch& jewelry, sanitary, home appliance, hotel products etc.Coating film performance:

(1) The coating is uniform, dense, with good adhesion, high hardness and low friction factor.

(2) The color does not fade over 2-3 years, which can meet the ROHS environmental standard.

(3) High physical property, good abrasion resistance; non-stick dirt on the surface of the coating.

(4) Stable performance, perspiration resistance/salt mist/abrasion/bend/RCA are all qualified.

The coating experts of your own company: Full set solution for the coating production.

HCVAC can help you to enter the PVD coating easily by our vacuum coating machine and full range service. We will provide with most suitable technology according to your requirements.

We will make the special coating solution for each customer; Combine the full set production technicto meet your requirements, to ensure high efficiency of production.

Easy to implement

To many people unfamiliar with the process, PVD coating technology seems complicated. However, with the right investments and a good support, it is easier than expected. HCVAC has developed a turnkey coating process that makes a PVD coating centre easy to implement. A complete coating process consists of several steps: Stripping (depending on the parts history); Pre-treatment; Quality control; Cleaning & drying; Fixturing & visual inspection; PVD coating; Quality control & thickness measurement and post-treatment (depending on the application). These steps are all available from one partner: HCVAC Technology, including mature technics and coatings.

Technical Parameter:

FAQs of HCVAC Stainless Steel Flatware Pvd Titanium Coating Machine Vacuum Chamber:

Q: Is the HCVAC Stainless Steel Flatware Pvd Titanium Coating Machine Vacuum Chamber an automatic machine?

A: Yes, it is an automatic machine.Q: What type of coating machine is the HCVAC Stainless Steel Flatware Pvd Titanium Coating Machine Vacuum Chamber?

A: It is an industrial coating machine and a metal coating machine.Q: What is the dimension of the HCVAC Stainless Steel Flatware Pvd Titanium Coating Machine Vacuum Chamber?

A: The dimension can be customized according to the specific requirements.Q: What is the voltage requirement for the HCVAC Stainless Steel Flatware Pvd Titanium Coating Machine Vacuum Chamber?

A: The voltage requirement is 380V.Q: What material is the HCVAC Stainless Steel Flatware Pvd Titanium Coating Machine Vacuum Chamber made of?

A: It is made of stainless steel.Enter Buying Requirement Details

Send Inquiry

Send Inquiry Call Me Free

Call Me Free