Call us now : +8618401585304

HCVAC Vacuum Metallizing Coating Machine for Automotive Lamp Reflector

60000-200000 USD ($)/Set

Product Details:

- Product Type PVD Vacuum coating machine

- Material Stainless Steel

- Type Industrial Coating Machine Metal Coating Machine

- Weight (kg) 5-8 Ton

- Coating Head Other

- Coating Material Other

- Computerized Yes

- Click to View more

X

HCVAC Vacuum Metallizing Coating Machine for Automotive Lamp Reflector Price And Quantity

- 1 Set

- 60000-200000 USD ($)/Set

HCVAC Vacuum Metallizing Coating Machine for Automotive Lamp Reflector Product Specifications

- 5-8 Ton

- Coating

- Industrial Coating Machine Metal Coating Machine

- One year Warranty

- Other

- 380V

- Yes

- PLC Control

- Silver, Golden, Black, Rose Gold, Pink, Bronze, Coffee

- Yes

- Other

- customized

- Stainless Steel

- 45-90KW

- Yes

- PVD Vacuum coating machine

HCVAC Vacuum Metallizing Coating Machine for Automotive Lamp Reflector Trade Information

- FOB SHENZHEN

- Letter of Credit (L/C) Telegraphic Transfer (T/T)

- 60 Days

- Contact us for information regarding our sample policy

- Wooden Package or carton package

- Eastern Europe Middle East Africa Western Europe Asia

- All India

- CE, ISO

Product Description

We provide with full set of head lamp coating process.

We produce both vertical and horizontal for our full automatic car light vacuum coating equipment.Main function of this machine including high voltage ion bombard, coat aluminum film and hard SiOx protective film at one time inside the vacuum chamber. Hard SiO protective film imporves the capability of anti- nitriding and keeps the high reflective rate of aluminum film for long time.

The reflective coating film reaches the national standard for the car light. It passed the acid, alkali, salt test. Machine adopts the computor control and monitor of the running state and coating process. It can improve the working efficiency and ensure the stability and consistency of the product quality, reduce the effect of human factors.

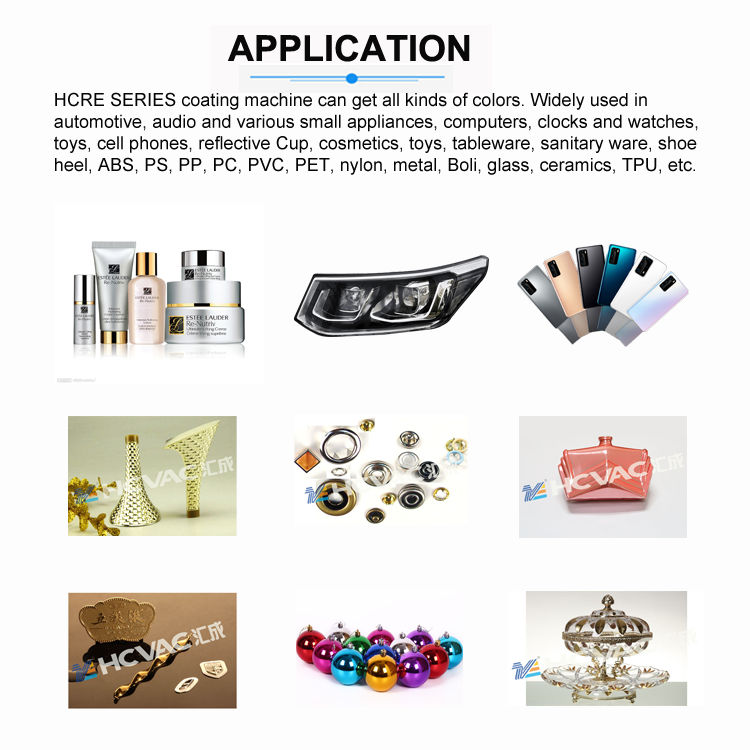

Application:

Car light reflective film, reflector cup, headlamp, rear lamp, turn light, car license plate lamp etc. front lamp including: halogen lamp, xenon vapor lamp, dipped headlight, far reaching headlamp, front turning light, front position light (width light, show the position of the car), front fog lamp; rear lamp including real light, backup reversing lamp, break lamp, rear fog lamp, real turning light.

Electroplating effects: General electroplating-face, dumb-(semi-mute, all dumb), the electroplating process wrinkles, lampworking, raindrops, seven colors;

Coating color: Gold, silver, red, blue, green, purple, multi color, and so on.

Working Principle:

The whole process like vacuum pumping, plasma cleaning, Al film and the SiOx protective film coating, deflating etc. is all running fully automaticly.

Two doors (optional) with 6-axis (also 8 axis optional) rotation &revolution jig and evaporation motor. When handle the workpiece in one door. It can upload and unload the workpiece and install AL materials in another door at the same time. So the production performance is very excellent.

The aluminum deposition adopts resistance heating evaporation source, complex three-dimensional structure can also be uniform deposited.

SiOx protective film coating system is optional.

The coating experts of your own company: Full set solution for the coating production

HCVAC can help you to enter the PVD coating easily by our vacuum coating machine and full range service. We will provide with most suitable technology according to your requirements.

We will make the special coating solution for each customer; combine the full set production technics to meet your requirements, to ensure high efficiency of production.

We developed a complete after-sales system and effective service measures. Company now owns a professional after-sales service team with more than ten experienced engineers.

Technical parameter:

Mode

Dimension

|

JTZ-1214 |

JTZ-1418 |

JTZ-1619 |

JTZ-1820 |

|

|

1200*1400mm |

1400*1800mm |

1600*1900mm |

1800*2000mm |

|

|

Film type |

Meal film, translucent film, nonconductive film, electromagnetism shield film, dielectric film, etc. |

|||

|

Power source |

Resistance evaporation power, DC magnetron power, RF power |

|||

|

Sputtering and electrode structure |

Column magnetron targets, plane rectangle targets, twin targets, evaporation electrode. |

|||

|

Vacuum chamber structure |

Vertical double door, Vertical single door, pump system postposition, horizontal single door, pump system for side. |

|||

|

Ultimate vacuum |

4.0*10-4pa |

|||

|

Vacuum system |

Diffusion pump +Roots pump +Mechanical pump +Holding pump |

|||

|

Pump time |

Pump from atmosphere to 8.5*10-3,15 minutes |

|||

|

Control mode |

Manual/Automatic all in one mode, Touch screen + PLC |

|||

FAQs of HCVAC Vacuum Metallizing Coating Machine for Automotive Lamp Reflector:

Q: What type of coating does the HCVAC Vacuum Metallizing Coating Machine provide?

A: The machine provides industrial metal coating for automotive lamp reflectors.Q: Does the machine have a humidification system?

A: Yes, it is equipped with a humidification system.Q: What is the control system of the machine?

A: The machine has a PLC control system.Q: What is the voltage requirement for the machine?

A: The machine operates on 380V voltage.Q: Is the HCVAC Vacuum Metallizing Coating Machine automatic?

A: Yes, it is an automatic machine.Enter Buying Requirement Details

Send Inquiry

Send Inquiry Call Me Free

Call Me Free