हमें कॉल करें now : +8618401585304

HCVAC ऑटोमोटिव लैंप लाइटिंग वैक्यूम मेटलाइजिंग कोटिंग मशीन/उपकरण

60000 USD ($)/Set

उत्पाद विवरण:

- प्रॉडक्ट टाइप पीवीडी वैक्यूम कोटिंग मशीन

- मटेरियल अन्य

- टाइप करें मेटल कोटिंग मशीन औद्योगिक कोटिंग मशीन

- वजन (किग्रा) 5-8 टन टन

- कोटिंग हेड अन्य

- कम्प्यूटरीकृत हाँ

- ऑटोमेटिक हाँ

- अधिक देखने के लिए क्लिक करें

X

HCVAC ऑटोमोटिव लैंप लाइटिंग वैक्यूम मेटलाइजिंग कोटिंग मशीन/उपकरण मूल्य और मात्रा

- 1

- सेट/सेट्स

HCVAC ऑटोमोटिव लैंप लाइटिंग वैक्यूम मेटलाइजिंग कोटिंग मशीन/उपकरण उत्पाद की विशेषताएं

- लेप करना

- एक साल की वारंटी, आजीवन रखरखाव

- 5-8 टन टन

- अन्य

- हाँ

- 380V वोल्ट (v)

- PLC नियंत्रण

- हाँ

- चांदी, सुनहरा, काला, गुलाबी सोना, गुलाबी, कांस्य, कॉफ़ी

- अन्य

- मेटल कोटिंग मशीन औद्योगिक कोटिंग मशीन

- पीवीडी वैक्यूम कोटिंग मशीन

HCVAC ऑटोमोटिव लैंप लाइटिंग वैक्यूम मेटलाइजिंग कोटिंग मशीन/उपकरण व्यापार सूचना

- एफओबी शेन्ज़ेन

- लेटर ऑफ क्रेडिट (एल/सी) टेलीग्राफिक ट्रांसफर (T/T)

- 60 दिन

- लकड़ी का पैकेज या कार्टन पैकेज

- पूर्वी यूरोप मिडल ईस्ट पश्चिमी यूरोप एशिया अफ्रीका

- ऑल इंडिया

- सीई, आईएसओ

उत्पाद वर्णन

The reflective coating film reaches the national standard for the car light. It passed the acid, alkali, salt test. Machine adopts the computor control and monitor of the running state and coating process. It can improve the working efficiency and ensure the stability and consistency of the product quality, reduce the effect of human factors.

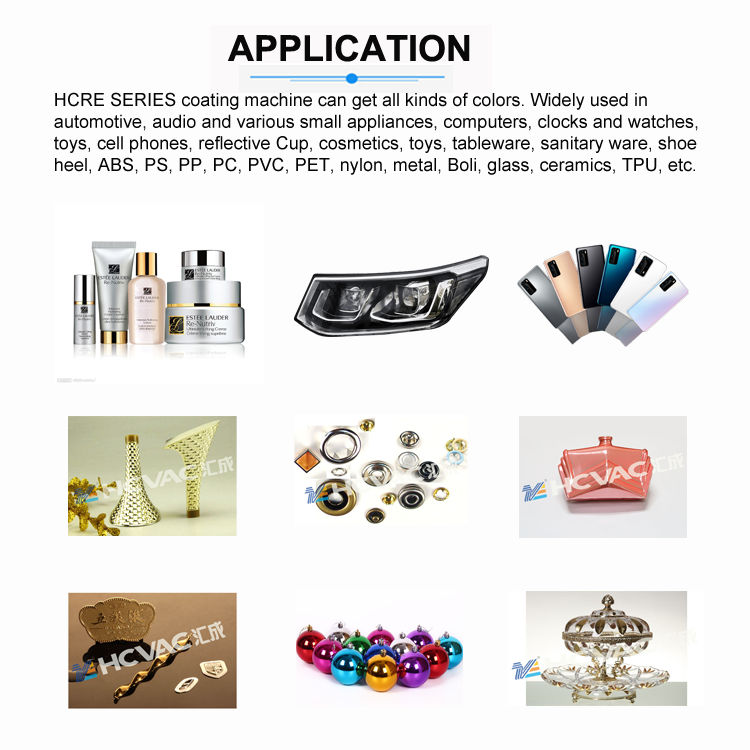

Application: HCVAC can help you to enter the PVD coating easily by our vacuum coating machine and full range service. We will provide with most suitable technology according to your requirements. We will make the special coating solution for each customer; combine the full set production technicto meet your requirements, to ensure high efficiency of production. Easy to implement To many people unfamiliar with the process, PVD coating technology seems complicated. However, with the right investments and a good support, it is easier than expected. HCVAC has developed a turnkey coating process that makes a PVD coating centre easy to implement. A complete coating process consists of several steps: stripping (depending on the parts history); pre-treatment; quality control; cleaning & drying; fixturing & visual inspection; PVD coating; quality control & thickness measurement and post-treatment (depending on the application). These steps are all available from one partner: HCVAC Technology, including mature technics and coatings. A special after-sales service hotline is set up to provide the customers with satisfactory problem solutions and technical support. Technical parameters: Mode Dimension ZZ-1214 ZZ-1416 ZZ-1618 ZZ-1820 1200*1400mm 1400*1600mm 1600*1800mm 1800*2000mm Film Type Semitransparent film, non-conducting film, gold, silver, red, blue, green, purple, seven color, etc. Power source Type Thermal evaporation power, ion bombard power, RF power Vacuum chamber structure Vertical double/single door, horizontal single door, pump system postposition Ultimate vacuum 8.0*10-4Pa Vacuum system Diffusion pump +Roots pump +Mechanical pump +Holding pump Pump time Pump from atmosphere to 5.0*10-2,6 minutes Workpiece motion mode Public rotation/Frequency control Control mode Manual/Automatic all-in-one mode, Touching screen+PLC Remark We can design the dimension of the vacuum chamber according to customers demand.

Lamps, decorative material, automotive reflector plate etc.

Car light reflective film, reflector cup, headlamp, rear lamp, turn light, car license plate lamp etc. Front lamp including: Halogen lamp, xenon vapor lamp, dipped headlight, far reaching headlamp, front turning light, front position light (width light, show the position of the car), front fog lamp; Rear lamp including real light, backup reversing lamp, break lamp, rear fog lamp, real turning light.

Characteristic: Reasonable structure, even film, good-quality film forming, quick pumping speed, the cycle of short, high efficiency and easy operation, low energy consumption and performance advantages of stability.

Electroplating effects: General electroplating-face, dumb-(semi-mute, all dumb), the electroplating process wrinkles, lampworking, raindrops, seven colors;

ISO 9001 standard to ensure the quality can meet the customers requirements.

Please feel free to contact us for further information!

FAQs of HCVAC Automotive Lamp Lighting Vacuum Metallizing Coating Machine / Equipment:

Q: What is the weight of the HCVAC Automotive Lamp Lighting Vacuum Metallizing Coating Machine / Equipment?

A: The weight of the machine is 5-8 TON.Q: What is the warranty for this product?

A: The product comes with a one year warranty and lifetime maintenance.Q: What are the available colors for the coating?

A: The available colors for coating are Silver, Golden, Black, Rose Gold, Pink, Bronze, and Coffee.Q: Is the machine automatic?

A: Yes, the machine is automatic.Q: What is the power consumption of the machine?

A: The power consumption is 45-90KW.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें