हमें कॉल करें now : +8618401585304

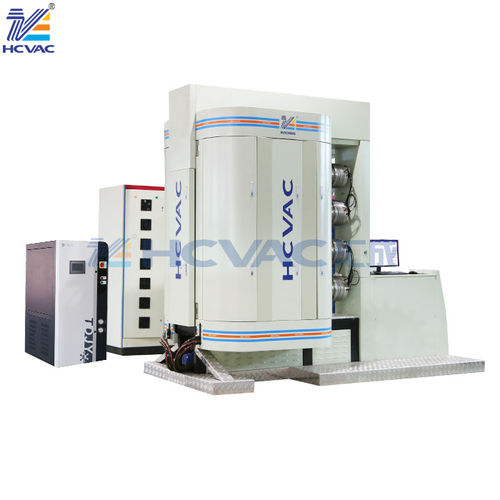

आभूषण, घड़ी, फर्नीचर, नल के लिए HCVAC प्लाज्मा PVD कोटिंग मशीन सिस्टम

100000-300000 USD ($)/Set

उत्पाद विवरण:

- प्रॉडक्ट टाइप पीवीडी वैक्यूम कोटिंग मशीन

- मटेरियल स्टेनलेस स्टील

- टाइप करें औद्योगिक कोटिंग मशीन मेटल कोटिंग मशीन

- वजन (किग्रा) 5-8 टन

- कम्प्यूटरीकृत हाँ

- ऑटोमेटिक हाँ

- कंट्रोल सिस्टम PLC नियंत्रण

- अधिक देखने के लिए क्लिक करें

X

आभूषण, घड़ी, फर्नीचर, नल के लिए HCVAC प्लाज्मा PVD कोटिंग मशीन सिस्टम मूल्य और मात्रा

- 1

- सेट/सेट्स

- सेट/सेट्स

आभूषण, घड़ी, फर्नीचर, नल के लिए HCVAC प्लाज्मा PVD कोटिंग मशीन सिस्टम उत्पाद की विशेषताएं

- 5-8 टन

- स्टेनलेस स्टील

- पीवीडी वैक्यूम कोटिंग मशीन

- PLC नियंत्रण

- चांदी, सुनहरा, काला, गुलाबी सोना, गुलाबी, कांस्य, कॉफ़ी

- लेप करना

- 380V

- हाँ

- 45-150 किलोवाट

- एक साल की वारंटी, आजीवन रखरखाव

- औद्योगिक कोटिंग मशीन मेटल कोटिंग मशीन

- हाँ

- अनुकूलित

आभूषण, घड़ी, फर्नीचर, नल के लिए HCVAC प्लाज्मा PVD कोटिंग मशीन सिस्टम व्यापार सूचना

- एफओबी शेन्ज़ेन

- टेलीग्राफिक ट्रांसफर (T/T) लेटर ऑफ क्रेडिट (एल/सी)

- 60 दिन

- हमारी नमूना नीति के बारे में जानकारी के लिए हमसे संपर्क करें

- लकड़ी का पैकेज या कार्टन पैकेज

- पूर्वी यूरोप पश्चिमी यूरोप मिडल ईस्ट एशिया अफ्रीका

- ऑल इंडिया

- सीई, आईएसओ

उत्पाद वर्णन

HCVAC Plasma PVD coating machine system for jewelry, watch, furniture, faucet

This machine mainly integrate the technology of arc ion evaporation, combining the ion source and the pulse bias voltage. It is full automation control when coating films. The coating will be good adhesion, scratch-proof.

The principle of vacuum electric arc ion coating is based on cold cathode, self-sustained arc discharge plasma evaporation, ionization material, combine pulsed bias technical to improve the energy and activity of deposited particles, and enhance the properties of coating. It can deposit coatings on the surface of metal as well as non-metal.

The colros we can get:

*IPG, IP yellow, Zr-gold, Ti-gold, champagne gold

* 14K,18K,24K, rose gold real gold

*IPU blue, dark blue, grey blue, red purple

*IP light titanium, light grey, dark grey, black

*IPB light coffee, dark coffee, brown

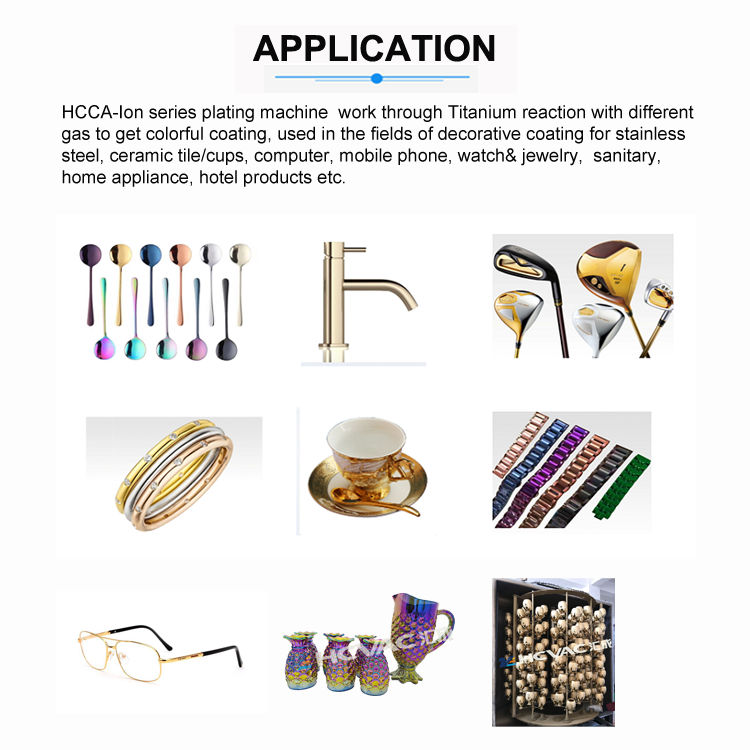

Applications:

*Watch Parts: Watch Case, Watch Strap and accessories

*Jewelry: Ring, Bracelet, Necklace, Pendant etc.

*Golf Head, Golf shafts etc.

*Kitchen&Bath Fitting: Stainless Steel, Brass, Zamak, ABS Parts.

*Hardware: Buckle, Fashion Hardware, LOGO etc.

*Ceramics and Glass Parts

Coating film performance:

(1) The coating is uniform, dense, with good adhesion, high hardness and low friction factor.

(2) The color does not fade over 2-3 years, which can meet the ROHS environmental standard.

(3) High physical property, good abrasion resistance; non-stick dirt on the surface of the coating.

(4) Stable performance, perspiration resistance/salt mist/abrasion/bend/RCA are all qualified.

The coating experts of your own company: Full set solution for the coating production.

HCVAC can help you to enter the PVD coating easily by our vacuum coating machine and full range service. We will provide with most suitable technology according to your requirements.

We will make the special coating solution for each customer; Combine the full set production technicto meet your requirements, to ensure high efficiency of production.

Easy to implement

To many people unfamiliar with the process, PVD coating technology seems complicated. However, with the right investments and a good support, it is easier than expected. HCVAC has developed a turnkey coating process that makes a PVD coating centre easy to implement. A complete coating process consists of several steps: Stripping (depending on the parts history); Pre-treatment; Quality control; Cleaning & drying; Fixturing & visual inspection; PVD coating; Quality control & thickness measurement and post-treatment (depending on the application). These steps are all available from one partner: HCVAC Technology, including mature technics and coatings.

Techinical parameters:

LH-800 | LH-1250 | LH-1416 | LH-1618 | |

800*1000mm | 1200*1500mm | 1400*1600mm | 1600*1800mm | |

Coating mode and main confirguration | Eight multi-arc targets | Twelve multi-arc targets | Fourteen multi-arc targets | Twenty multi-arc targets |

Power source | Electric-arc power, Filament power, Pulsed bias power supply | |||

Process gas control | Mass flowmeter + Electromagnetic ceramic valve | |||

Vacuum chamber structure | Vertical side opening door, pump system postposition, double water cooling | |||

Vacuum system | Molecule pump +Roots pump +Mechanical pump(5.0*10 -5 Pa) Diffusion pump +Roots pump +Mechanical pump(5.0*10 -4 Pa) | |||

Workpiece baking temperature | Normal temperature to 350 centi-degree PID control, radiation heating. | |||

Workpiece motion mode | Public rotation Frequency control: 0-20 rotation per minute | |||

Measure mode | Number display composite vacuum gauge: from atmosphere to 1.0*10 -5 Pa | |||

Control mode | Manual/Automatic/PC/PLC + HMI/PC four choice of control mode | |||

Remark | We can design the dimension of the equipment according to customers special technique requirement. | |||

FAQs of HCVAC Plasma PVD Coating Machine System for Jewelry, Watch, Furniture, Faucet:

Q: What is the voltage requirement for HCVAC Plasma PVD Coating Machine System?

A: The voltage requirement for HCVAC Plasma PVD Coating Machine System is 380V.Q: What is the material used for the construction of the machine?

A: The machine is constructed using stainless steel material.Q: Is the HCVAC Plasma PVD Coating Machine computerized and automatic?

A: Yes, the HCVAC Plasma PVD Coating Machine is computerized and automatic.Q: What are the color options available for coating with this machine?

A: The color options available for coating with this machine are silver, golden, black, rose gold, pink, bronze, and coffee.Q: What is the warranty provided for HCVAC Plasma PVD Coating Machine System?

A: The machine comes with a one-year warranty and lifetime maintenance.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें