हमें कॉल करें now : +8618401585304

सिरेमिक पॉटरी टेबलवेयर के लिए HCVAC PVD वैक्यूम कोटिंग मशीन

100000-500000 USD ($)/Set

उत्पाद विवरण:

- प्रॉडक्ट टाइप कोटिंग उत्पादन लाइन

- मटेरियल स्टेनलेस स्टील

- टाइप करें औद्योगिक कोटिंग मशीन मेटल कोटिंग मशीन

- वजन (किग्रा) 5-8 टन

- कम्प्यूटरीकृत हाँ

- ऑटोमेटिक हाँ

- कंट्रोल सिस्टम PLC नियंत्रण

- अधिक देखने के लिए क्लिक करें

X

सिरेमिक पॉटरी टेबलवेयर के लिए HCVAC PVD वैक्यूम कोटिंग मशीन मूल्य और मात्रा

- सेट/सेट्स

- सेट/सेट्स

- 1

सिरेमिक पॉटरी टेबलवेयर के लिए HCVAC PVD वैक्यूम कोटिंग मशीन उत्पाद की विशेषताएं

- औद्योगिक कोटिंग मशीन मेटल कोटिंग मशीन

- चांदी, सुनहरा, काला, गुलाबी सोना, गुलाबी, कांस्य, कॉफ़ी

- स्टेनलेस स्टील

- हाँ

- लेप करना

- अनुकूलित

- हाँ

- 5-8 टन

- PLC नियंत्रण

- एक साल की वारंटी, आजीवन रखरखाव

- 45-150 किलोवाट

- 380V

- कोटिंग उत्पादन लाइन

सिरेमिक पॉटरी टेबलवेयर के लिए HCVAC PVD वैक्यूम कोटिंग मशीन व्यापार सूचना

- एफओबी शेन्ज़ेन

- लेटर ऑफ क्रेडिट (एल/सी) टेलीग्राफिक ट्रांसफर (T/T)

- 60 दिन

- लकड़ी का पैकेज या कार्टन पैकेज

- पश्चिमी यूरोप पूर्वी यूरोप मिडल ईस्ट अफ्रीका एशिया

- ऑल इंडिया

- सीई, आईएसओ

उत्पाद वर्णन

HCVAC PVD Vacuum Coating Machine for Ceramic Pottery Tableware

1. Brief intorduction:

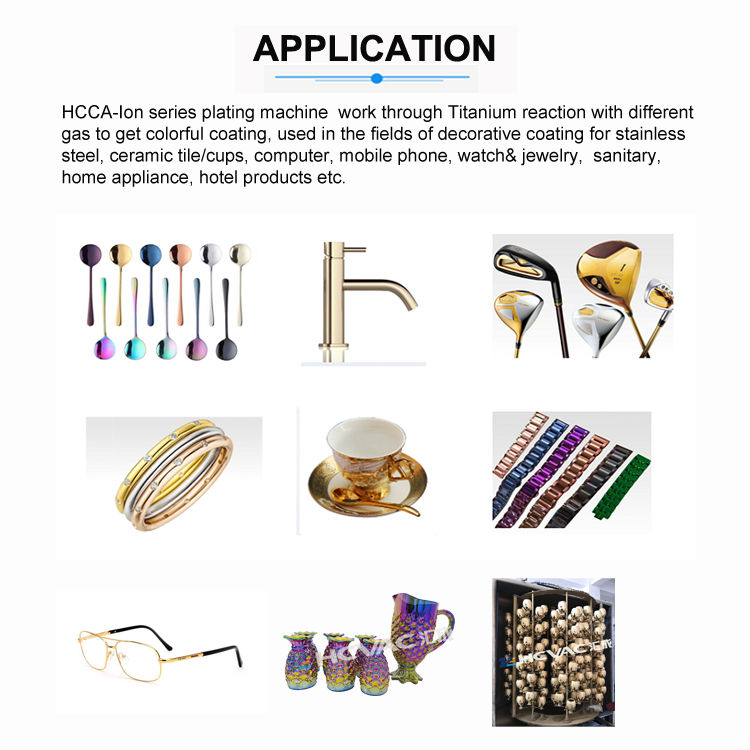

The machine can coat ceramic tiles, ceramic tableware, porcelain tiles, floor tiles, glass mosaic. Glass tiles. Beside ceramic, you can also coat metal, glass products.

The machine is used to deposit TiN(gold color), Ti (silver color) and other coating on ceramic products. Thus it can replace the traditional paint gold, enhence the adhension, saves cost and improve production efficiency.

2. Detailed description: Applied industry: It can be used to coat metal film, titanium nitride titanium carbide, and zirconium nitride, chromium nitride and titanium, nickel, chromium, copper and other Company Introduction: Technical Parameters:

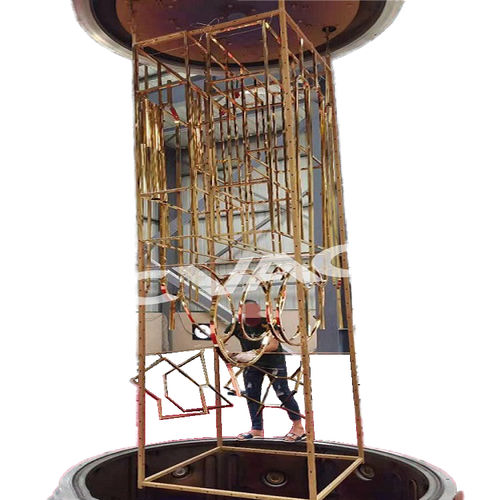

This is a ion coating machine of efficiency, harmless and pollution-free. It has the features of fast deposition rate, great ionization rate, big ion energy, easy operation, low cost, large productive capacity, etc.

The principle of vacuum electric arc ion coating is intergrating cold cathode, arc discharge Self-sustained light, ionization plating material with pulse technique to improve depostion particle energy and survival rate and the properties of the film. It can coat on the surface of the metal as well as nonmetal.

Compounds film, multi-layer super-hard film, nitrogen-doped titanium film and the alloy film, titanium nitride mixed with gold-plated titanium nitride film.

Our company focusing on improve roundness electronic arc evaporation source and develop high performance rectangular flat electric arc evaporation source. Meanwhile, we had install it into new machine.

The coating experts of your own company: Full set solution for the coating production.

HCVAC can help you to enter the PVD coating easily by our vacuum coating machine and full range service. We will provide with most suitable technology according to your requirements.

We will make the special coating solution for each customer; Combine the full set production technics to meet your requirements, to ensure high efficiency of production.

Mode

Dimension

LH-800

LH-1250

LH-1416

LH-1618

800*1000mm

1200*1500mm

1400*1600mm

1600*1800mm

Coating mode and main confirguration

Eight multi-arc targets

Twelve multi-arc targets

Fourteen

multi-arc targets

Twenty

multi-arc targets

Power source

Electric-arc power, Filament power, Pulsed bias power supply

Process gas control

Mass flowmeter + Electromagnetic ceramic valve

Vacuum chamber structureVertical side opening door, pump system postposition, double water cooling

Vacuum system

Molecule pump +Roots pump +Mechanical pump(5.0*10 -5 Pa)

Diffusion pump +Roots pump +Mechanical pump(5.0*10 -4 Pa)

Workpiece baking temperatureNormal temperature to 350 centi-degree PID control, radiation heating.

Workpiece motion mode

Public rotation Frequency control: 0-20 rotation per minute

Measure mode

Number display composite vacuum gauge: from atmosphere to 1.0*10 -5 Pa

Control mode

Manual/Automatic/PC/PLC + HMI/PC four choice of control mode

Remark

We can design the dimension of the equipment according to customers special technique requirement.

FAQs of HCVAC PVD Vacuum Coating Machine for Ceramic Pottery Tableware:

Q: Is the HCVAC PVD Vacuum Coating Machine computerized?

A: Yes, the HCVAC PVD Vacuum Coating Machine is computerized.Q: What type of control system does the machine have?

A: The machine has a PLC control system.Q: What is the voltage requirement for the machine?

A: The voltage requirement for the machine is 380V.Q: What is the warranty for the HCVAC PVD Vacuum Coating Machine?

A: The machine comes with a one year warranty and lifetime maintenance.Q: What are the available colors for the coating?

A: The available colors for the coating are silver, golden, black, rose gold, pink, bronze, and coffee.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें