हमें कॉल करें now : +8618401585304

प्रवाहकीय परत के लिए HCVAC रोल-टू-रोल स्पटर सिस्टम

300000 USD ($)/Set

उत्पाद विवरण:

- प्रॉडक्ट टाइप पीवीडी वैक्यूम कोटिंग मशीन

- सामान्य उपयोग पीईटी, ओपीपी, पीवीसी, सीपीपी, नकली-विरोधी सामग्री, गर्म मुद्रांकन पन्नी और सतह सजावट प्लास्टिक फिल्म

- मटेरियल स्टेनलेस स्टील

- टाइप करें औद्योगिक कोटिंग मशीन मेटल कोटिंग मशीन

- वजन (किग्रा) 10-20 टन

- कोटिंग हेड अन्य

- कम्प्यूटरीकृत हाँ

- अधिक देखने के लिए क्लिक करें

X

प्रवाहकीय परत के लिए HCVAC रोल-टू-रोल स्पटर सिस्टम मूल्य और मात्रा

- सेट/सेट्स

- 1

- सेट/सेट्स

प्रवाहकीय परत के लिए HCVAC रोल-टू-रोल स्पटर सिस्टम उत्पाद की विशेषताएं

- PLC नियंत्रण

- पीवीडी वैक्यूम कोटिंग मशीन

- औद्योगिक कोटिंग मशीन मेटल कोटिंग मशीन

- हाँ

- हाँ

- हाँ

- इलेक्ट्रिक

- 380V वोल्ट (v)

- स्टेनलेस स्टील

- इलेक्ट्रिक

- 10-20 टन

- सोना, चाँदी, गुलाबी सोना, काला, नीला इत्यादि

- पीईटी, ओपीपी, पीवीसी, सीपीपी, नकली-विरोधी सामग्री, गर्म मुद्रांकन पन्नी और सतह सजावट प्लास्टिक फिल्म

- लेप करना ऊर्जा की कम खपत हाई स्पीड उच्च परिशुद्धता

- अन्य

- एक साल की वारंटी, आजीवन रखरखाव

प्रवाहकीय परत के लिए HCVAC रोल-टू-रोल स्पटर सिस्टम व्यापार सूचना

- एफओबी शेन्ज़ेन

- लेटर ऑफ क्रेडिट (एल/सी) टेलीग्राफिक ट्रांसफर (T/T)

- 60 दिन

- हमारी नमूना नीति के बारे में जानकारी के लिए हमसे संपर्क करें

- लकड़ी का पैकेज या कार्टन पैकेज

- पूर्वी यूरोप पश्चिमी यूरोप मिडल ईस्ट अफ्रीका एशिया

- ऑल इंडिया

- सीई, आईएसओ

उत्पाद वर्णन

HCVAC Roll to Roll Web Vacuum coating machine

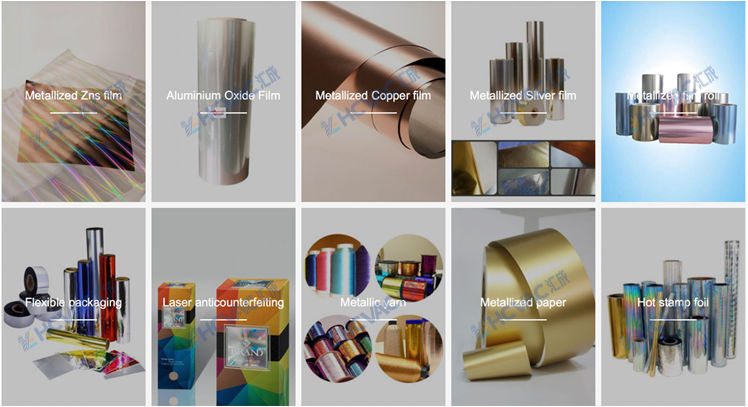

e ITO can be used for cold lighting metarial, SiO2 on the cutton can be used as anti-electromagnetic suit, sponge coated with Ni can be used to made Ni-H battery, e-book and flexiable display device.

Metal and oxide barrier films for the packaging industry

Color-shifting and holographic films for security and anti-counterfeit applications

In-situ patterned metal layers for special flexible packaging

Multi-process, customer-configurable deposition systems for flexible electronics and advanced technology applications.

Web Widths from 50mm to 500mm

Plastic & Metal Foils, fabric,Textiles,Flexible Glass & Ceramics

Industry Leading Compact Ergonomic Design

Up to 5 Configurable Deposition Zones

Evaporation (Thermal or E-beam)

AC or DC Planar Sputter Magnetrons

AC or DC Rotary Sputter MagnetronsPlasma surface treatment

Versatile Web PathsWeb forward and backward enables multi-layer coating designs

Non-contact front surface web paths for defect free surfacesDrum mode for coating straps or individual substrates

Interlead removal and applicationThin film applications

Metallizaton

Optical

Decorative

Security

gnetic

hin Film Battery

High Temperature Superconductors

Medical Devices

Tribological (Wear) Coating

Display (LCD, OLED, Electronic paper) and lighting device based on plastic film (PET, PEN, etc.)

Thin-film photovoltaic cell based on metallic and plastic substrate.

window film

Substrates Processed

Polymers

Metal Foils

Textiles

Non-woven

Flexible Glass

Flexible Ceramics

Data Sheet

Substrate: polymer films, metal foils, fabrics, non-woven, porous and netted materials

ubstrate width: up to 600 mm

Polymer film thickness: 6 200 m

Metal foil thickness: 10 200 m

Porous material thickness: 1 2 mm

Coatings: TCO, metals, alloys, oxides, nitrides

Deposition sources: DC, MF, DC pulsed magnetrons, EB guns, resistive boats, vapor generators

Pretreatment: glow discharge, ion guns, magnetron discharge, inverse magnetrons

The equipment is: reasonable structure, coating evenly into good-quality, pumping speed, the cycle of short, high efficiency and easy operation, low energy consumption and performance advantages of stability.

FAQs of HCVAC roll-to-roll sputter systems for conductive layer:

Q: What is the power consumption range for HCVAC roll-to-roll sputter systems?

A: The power consumption for HCVAC roll-to-roll sputter systems ranges from 90KW to 500KW.Q: What is the warranty offered for HCVAC roll-to-roll sputter systems?

A: HCVAC roll-to-roll sputter systems come with a one year warranty and lifetime maintenance.Q: What type of materials can be used with the HCVAC roll-to-roll sputter systems?

A: The HCVAC roll-to-roll sputter systems can be used for PET, OPP, PVC, CPP, anti-counterfeit materials, hot stamping foil, and surface decoration plastic film.Q: What is the power source for the HCVAC roll-to-roll sputter systems?

A: The power source for HCVAC roll-to-roll sputter systems is electric.Q: Is the HCVAC roll-to-roll sputter system automatic?

A: Yes, the HCVAC roll-to-roll sputter system is automatic and computerized with PLC control.Q: What is the material of construction for HCVAC roll-to-roll sputter systems?

A: HCVAC roll-to-roll sputter systems are made of stainless steel.Q: What is the color options available for HCVAC roll-to-roll sputter systems?

A: The color options for HCVAC roll-to-roll sputter systems include gold, silver, rose gold, black, blue, and more.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें