Call us now : +8618401585304

HCVAC Sanitary Ware/Bathroom Fitting Parts (brass, zamak, plastic) PVD Decorative Coating Machine

150000-600000 USD ($)/Set

Product Details:

- Product Type PVD Vacuum coating machine

- Material Stainless Steel

- Type Industrial Coating Machine Metal Coating Machine

- Weight (kg) 5-8 Ton

- Coating Material Other

- Computerized Yes

- Automatic Yes

- Click to View more

X

HCVAC Sanitary Ware/Bathroom Fitting Parts (brass, zamak, plastic) PVD Decorative Coating Machine Price And Quantity

- 150000-600000 USD ($)/Set

- 1 Set

HCVAC Sanitary Ware/Bathroom Fitting Parts (brass, zamak, plastic) PVD Decorative Coating Machine Product Specifications

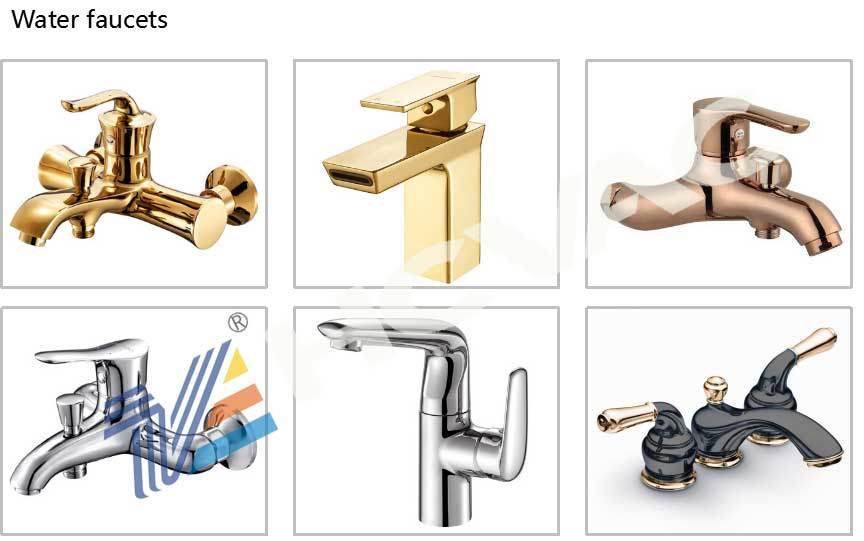

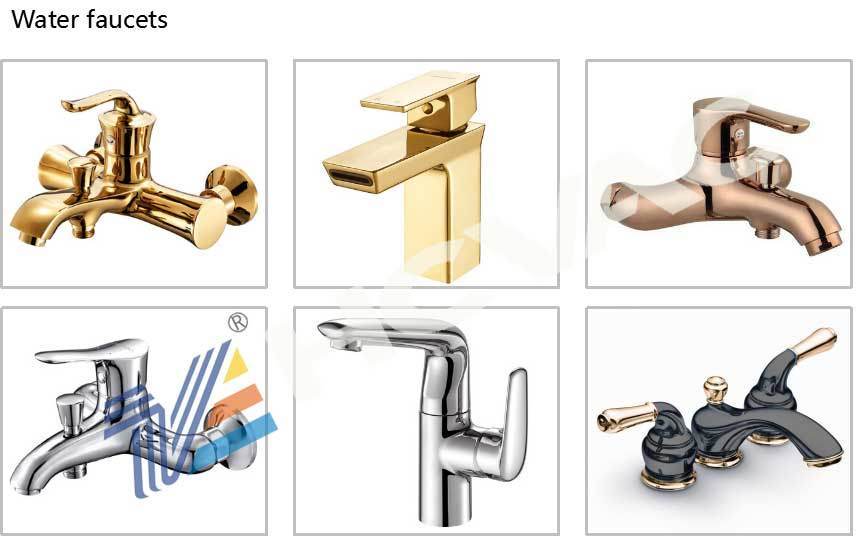

- Silver, Golden, Black, Rose Gold, Pink, Bronze, Coffee

- Yes

- One year warranty, lifetime maintenance

- Yes

- 380V

- 45-150KW

- Industrial Coating Machine Metal Coating Machine

- 5-8 Ton

- Stainless Steel

- PVD Vacuum coating machine

- Coating

- customized

- PLC Control

- Other

HCVAC Sanitary Ware/Bathroom Fitting Parts (brass, zamak, plastic) PVD Decorative Coating Machine Trade Information

- FOB SHENZHEN

- Letter of Credit (L/C) Telegraphic Transfer (T/T)

- 60 Days

- Contact us for information regarding our sample policy

- Wooden Package or carton package

- Western Europe Eastern Europe Middle East Asia Africa

- All India

- CE, ISO

Product Description

HCVAC Sanitary ware/bathroom fitting parts (brass, zamak, plastic) PVD decorative coating machine

The machine adopt Pvd coating technology(physical Vapor deposition) to get all kinds of color coating on sanitaryware,bathroom fitting,Brassware products, Especially we can do pvd coating on Plastic shower heads. it is totally different with the traditional electroplating way. the coating which get by PVD can provide you excellent coating,strong adhesion and finess coating. the color series including Chrome,gold,shinning Zr,TiN,Rosegold,black and Dark black and other color series. we service USA Kohler.Japan Toto group,China Jomoo,Delta and other famous companies for the coating project.

if you need any information related with the project,pls feel free to

The machine is mainly design for sanitary ware/bathroom fitting parts. Its equipped with several big size electrical arc evaporation sources and magnetron sputtering coating system, to deposit high performance metal decorative film on brass, zinc alloy, stainless steel, plastic and other metal parts surface. It can get all types of metal color series on substrate. The coating film includes TiN, Zr,T iCN, ZrCN, CrN, CrCN, brass, bronze, chrome etc. Color series includes AF, SN, BN, VF, BV, G, BX, TB, AF, SN, 96CB, CB, TXB, VS, S, BS, BRZ, BGD, PGD and so on. It can get different colors by adjusting coating technics. It is largely used in the sanitary ware/ Kitchen ware field.

It equips with the new target and the arc power supply, arc spot is stable. It is not easy running arc, the current is low and ionparticles is small. Applied to metal, ceramics, glass and other materials of the surface coating of hard metal film and metal compounds film. Pumping speed faster, vacuum stability, and superior quality film, widely used in hardware,watches, glasses, tools, dies, metal, glass, ceramics, building materials, and other surface treatment industry.

Technical parameters:

|

Mode |

HCCA-1215 |

HCCA-1612 |

HCCA-1619 |

|

1250*1500mm |

1600*1200mm |

1600*1900mm |

|

|

Power source |

Electric arc power, DC magnetron power, MF magnetron power, filament power, pulse power, linear ionized source. |

||

|

Process gas control |

Quality flowmeter + electromagnetism ceramic valve |

||

|

Vacuum chamber structure |

Vertical single(side) door, pump system postposition, double water-cooling |

||

|

Vacuum system |

Molecule pump +Roots pump +Mechanical pump(5.0*10 -5 Pa) |

||

|

Workpiece baking temperature |

|

||

|

Workpiece motion mode |

Public rotation Frequency control: 0-20 rotation per minute |

||

|

Measure mode |

Number display composite vacuum gauge: from atmosphere to 1.0*10 -5 Pa |

||

|

Control mode |

Manual/Automatic/PC/PLC + HMI/PC four choice of control mode |

||

|

Remark |

We can design the dimension of the equipment according to customers special technique requirement. |

||

|

|

FAQs of HCVAC Sanitary Ware/Bathroom Fitting Parts (brass, zamak, plastic) PVD Decorative Coating Machine:

Q: Is the HCVAC Sanitary Ware/Bathroom Fitting Parts PVD Decorative Coating Machine automatic?

A: Yes, it is automatic.Q: What is the power consumption of the machine?

A: The power consumption ranges from 45-150KW.Q: What type of control system does the machine have?

A: It has a PLC control system.Q: What is the warranty on the machine?

A: It comes with a one year warranty and lifetime maintenance.Q: What are the available colors for coating?

A: The available colors for coating are silver, golden, black, rose gold, pink, bronze, and coffee.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Call Me Free

Call Me Free