हमें कॉल करें now : +8613316689188

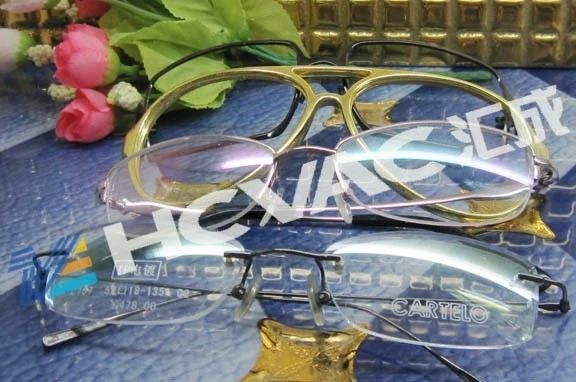

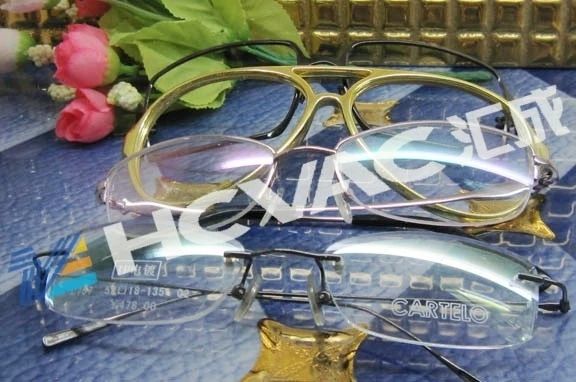

HCVAC चश्मा फ़्रेम टाइटेनियम PVD कोटिंग गोल्ड प्लेटिंग सिस्टम

120000 USD ($)/Set

उत्पाद विवरण:

- प्रॉडक्ट टाइप प्लाज्मा कोटिंग मशीन

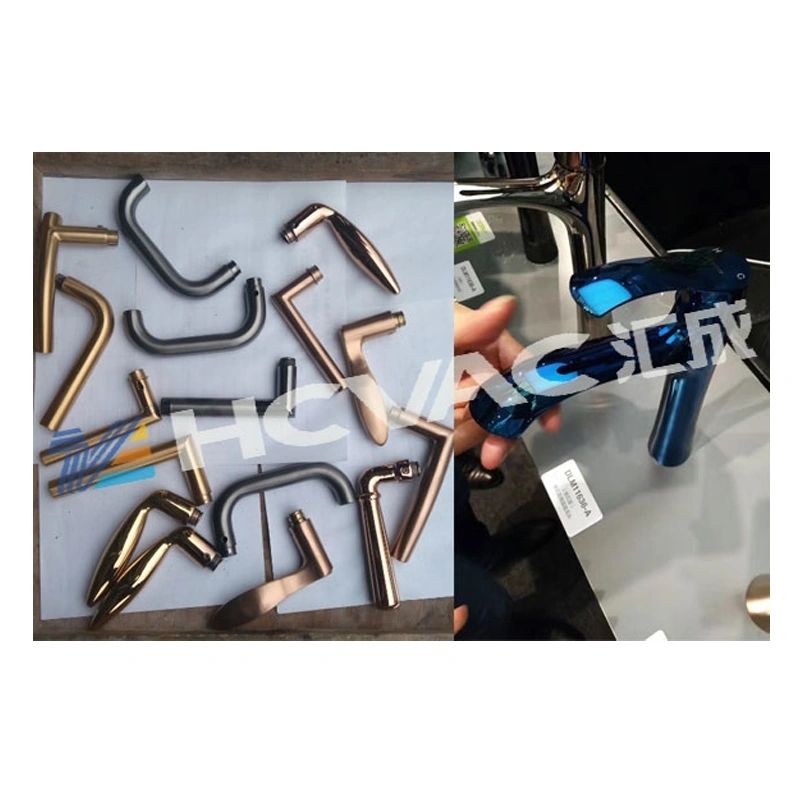

- सामान्य उपयोग इस मशीन का उपयोग बड़े पैमाने पर स्टेनलेस स्टील, सिरेमिक टाइल/कप, कंप्यूटर, मोबाइल फोन, घड़ी और आभूषण, स्वच्छता, घरेलू उपकरण, होटल उत्पादों आदि के लिए सजावटी कोटिंग के क्षेत्र में किया जाता है।

- मटेरियल स्टेनलेस स्टील

- टाइप करें औद्योगिक कोटिंग मशीन मेटल कोटिंग मशीन

- लेप करने की सामग्री अन्य

- कम्प्यूटरीकृत हाँ

- ऑटोमेटिक हाँ

- अधिक देखने के लिए क्लिक करें

X

HCVAC चश्मा फ़्रेम टाइटेनियम PVD कोटिंग गोल्ड प्लेटिंग सिस्टम मूल्य और मात्रा

- सेट/सेट्स

- सेट/सेट्स

- 1

HCVAC चश्मा फ़्रेम टाइटेनियम PVD कोटिंग गोल्ड प्लेटिंग सिस्टम उत्पाद की विशेषताएं

- इस मशीन का उपयोग बड़े पैमाने पर स्टेनलेस स्टील, सिरेमिक टाइल/कप, कंप्यूटर, मोबाइल फोन, घड़ी और आभूषण, स्वच्छता, घरेलू उपकरण, होटल उत्पादों आदि के लिए सजावटी कोटिंग के क्षेत्र में किया जाता है।

- प्लाज्मा कोटिंग मशीन

- PLC नियंत्रण

- एक साल की वारंटी

- हाँ

- स्टेनलेस स्टील

- इलेक्ट्रिक

- इलेक्ट्रिक

- अन्य

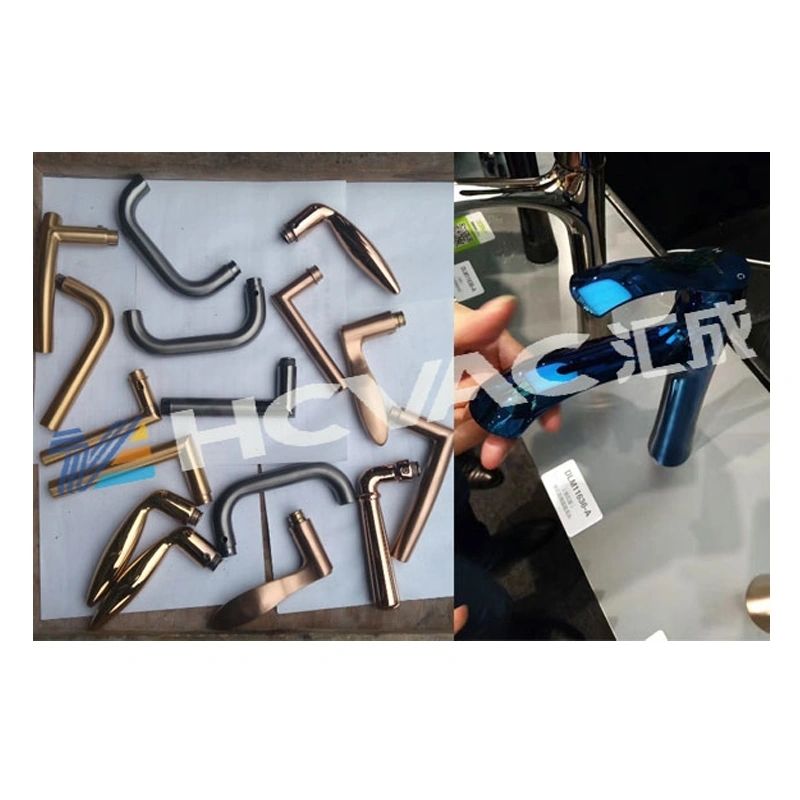

- सोना, रोज़गोल्ड, सिल्वर, काला, नीला, इंद्रधनुष आदि

- ऊर्जा की कम खपत हाई स्पीड लेप करना

- हाँ

- औद्योगिक कोटिंग मशीन मेटल कोटिंग मशीन

HCVAC चश्मा फ़्रेम टाइटेनियम PVD कोटिंग गोल्ड प्लेटिंग सिस्टम व्यापार सूचना

- एस सत्य है, चीन

- लेटर ऑफ क्रेडिट (एल/सी) टेलीग्राफिक ट्रांसफर (T/T)

- 60 दिन

- लकड़ी का पैकेज

- पूर्वी यूरोप पश्चिमी यूरोप मिडल ईस्ट दक्षिण अमेरिका एशिया अफ्रीका

- ऑल इंडिया

- सीई, आईएसओ

उत्पाद वर्णन

is a ion coating machine of efficiency, harmless and pollution-free. It has the features of fast deposition rate , great ionization rate, big ion energy,easy operation, low cost, large productive capacity, etc.Its the more advanced technology to replace traditional electroplating way.

Popular colors which could get by PVD:

Real gold an real rosegold coating

Imitation gold series: TiN, ZrN, TiN+Au, ZrN+Au

Rose Gold Series: TiCN, TiAlN, TiCN+Au--Cu, TiAlN+Au, Cu

Silver white series: CrN, CrSiN, Zr (micro N)

Grey series: Ti, stainless steel (S.S), (S.S) N

Coffee color series: TiCN, TiAlCN, ZrC

Blue series: TiO, CrO, TiALN

Black Series: TiC, TiC+iC, TiCN, TiAlN, TiAlCN, Ti (C, O) and DLC

| FEATURES |

The equipment integrates the plasma treatment, high-end cathode magnetron sputtering, resistance evaporation coating equipment, large load rotation frame and the automatic control technique. It has the reliable work, good repeatability and consistency., fast deposition rate, high adhesion, fine film, etc. The coating film is dense and hardness with low friction coefficient, to keep the smoothness of original workpiece surface, good flexibility, hard to break and fall.

The equipment makes full automation of the coating technology come true. It uses the vacuum coating technique to coat on the surface of the base material. It has the features of low cost, high qualification rate, green environmental protection etc.

| APPLICATION |

It can be used to coat metal film, titanium nitride, titanium carbide, and zirconium nitride, chromium nitride and titanium, nickel, chromium, copper , and other compounds film, multi-layer super-hard film, nitrogen-doped titanium film and the alloy film ( TiN, TiC, TiCN, TiAlN, CrN, Cu, Au, Al2O3and other decorative films etc.) and in a very short time to complete all the machining process, it is a highly efficient multi-functional coating equipment.

This machine is extensively used in the fields of decorative coating for stainless steel, ceramic tile/cups, computer, mobile phone, watch& jewelry, sanitary, home appliance, hotel products etc.

Real gold an real rosegold coating

Imitation gold series: TiN, ZrN, TiN+Au, ZrN+Au

Rose Gold Series: TiCN, TiAlN, TiCN+Au--Cu, TiAlN+Au, Cu

Silver white series: CrN, CrSiN, Zr (micro N)

Grey series: Ti, stainless steel (S.S), (S.S) N

Coffee color series: TiCN, TiAlCN, ZrC

Blue series: TiO, CrO, TiALN

Black Series: TiC, TiC+iC, TiCN, TiAlN, TiAlCN, Ti (C, O) and DLC

| FEATURES |

The equipment integrates the plasma treatment, high-end cathode magnetron sputtering, resistance evaporation coating equipment, large load rotation frame and the automatic control technique. It has the reliable work, good repeatability and consistency., fast deposition rate, high adhesion, fine film, etc. The coating film is dense and hardness with low friction coefficient, to keep the smoothness of original workpiece surface, good flexibility, hard to break and fall.

The equipment makes full automation of the coating technology come true. It uses the vacuum coating technique to coat on the surface of the base material. It has the features of low cost, high qualification rate, green environmental protection etc.

| APPLICATION |

It can be used to coat metal film, titanium nitride, titanium carbide, and zirconium nitride, chromium nitride and titanium, nickel, chromium, copper , and other compounds film, multi-layer super-hard film, nitrogen-doped titanium film and the alloy film ( TiN, TiC, TiCN, TiAlN, CrN, Cu, Au, Al2O3and other decorative films etc.) and in a very short time to complete all the machining process, it is a highly efficient multi-functional coating equipment.

This machine is extensively used in the fields of decorative coating for stainless steel, ceramic tile/cups, computer, mobile phone, watch& jewelry, sanitary, home appliance, hotel products etc

FAQs of HCVAC Eyeglass Frame Titanium PVD Coating Gold Plating System:

Q: What is the power consumption range of HCVAC Eyeglass Frame Titanium PVD Coating Gold Plating System?

A: The power consumption range of the system is 45-150KW.Q: What is the general use of this machine?

A: This machine is extensively used in the fields of decorative coating for stainless steel, ceramic tile/cups, computer, mobile phone, watch& jewelry, sanitary, home appliance, hotel products etc.Q: What type of control system does the machine have?

A: The machine has a PLC control system.Q: What warranty is provided with the HCVAC Eyeglass Frame Titanium PVD Coating Gold Plating System?

A: The system comes with a one year warranty.Q: What is the voltage requirement for this machine?

A: The voltage requirement for the machine is 380V.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें