हमें कॉल करें now : +8618401585304

HCVAC ग्लास कप बोतल गोल्डन कलर PVD वैक्यूम कोटिंग मशीन प्लांट

50000.00 - 150000.00 USD ($)/Set

उत्पाद विवरण:

- प्रॉडक्ट टाइप पीवीडी वैक्यूम कोटिंग मशीन

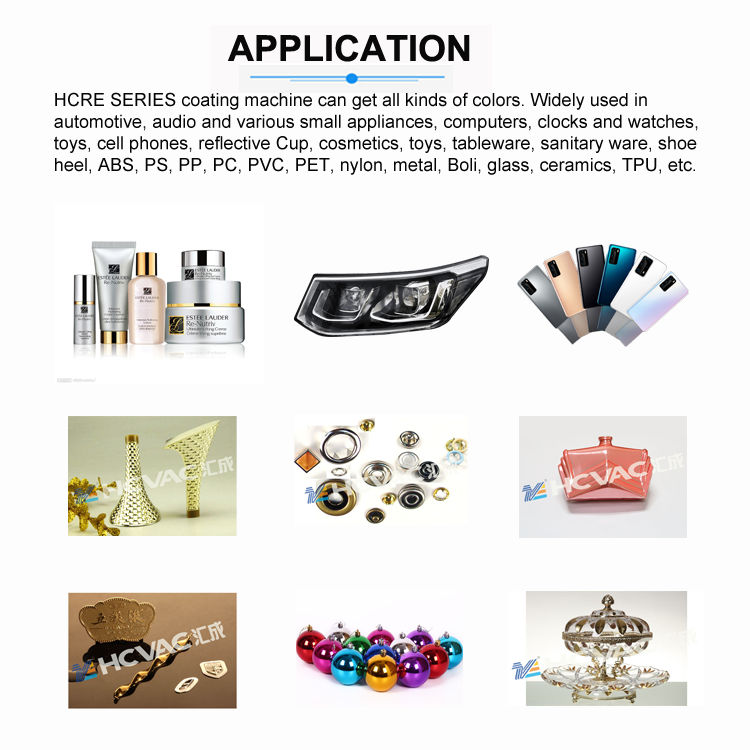

- सामान्य उपयोग ग्लास उत्पाद, वॉचबैंड, वॉचकेस, आभूषण, मोबाइल शेल, हार्डवेयर, टेबलवेयर, आदि

- मटेरियल स्टेनलेस स्टील

- टाइप करें औद्योगिक कोटिंग मशीन मेटल कोटिंग मशीन

- वजन (किग्रा) 5-8 टन

- कम्प्यूटरीकृत हाँ

- ऑटोमेटिक हाँ

- अधिक देखने के लिए क्लिक करें

X

HCVAC ग्लास कप बोतल गोल्डन कलर PVD वैक्यूम कोटिंग मशीन प्लांट मूल्य और मात्रा

- 1

- सेट/सेट्स

- सेट/सेट्स

HCVAC ग्लास कप बोतल गोल्डन कलर PVD वैक्यूम कोटिंग मशीन प्लांट उत्पाद की विशेषताएं

- 5-8 टन

- पीवीडी वैक्यूम कोटिंग मशीन

- हाँ

- ग्लास उत्पाद, वॉचबैंड, वॉचकेस, आभूषण, मोबाइल शेल, हार्डवेयर, टेबलवेयर, आदि

- हाँ

- लेप करना हाई स्पीड

- औद्योगिक कोटिंग मशीन मेटल कोटिंग मशीन

- स्टेनलेस स्टील

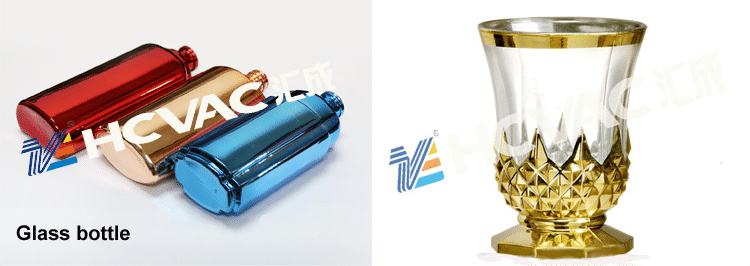

- सोना, चाँदी, गुलाबी सोना, काला, नीला इत्यादि

- एक साल की वारंटी, आजीवन रखरखाव

- हाँ

HCVAC ग्लास कप बोतल गोल्डन कलर PVD वैक्यूम कोटिंग मशीन प्लांट व्यापार सूचना

- एफओबी शेन्ज़ेन

- लेटर ऑफ क्रेडिट (एल/सी) टेलीग्राफिक ट्रांसफर (T/T)

- 60 दिन

- हमारी नमूना नीति के बारे में जानकारी के लिए हमसे संपर्क करें

- लकड़ी का पैकेज

- पूर्वी यूरोप पश्चिमी यूरोप मिडल ईस्ट अफ्रीका एशिया

- ऑल इंडिया

- सीई, आईएसओ

उत्पाद वर्णन

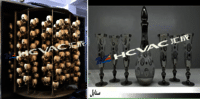

The principle of vacuum electric arc ion coating is based on cold cathode, self-sustained arc discharge plasma evaporation, ionization material, combine pulsed bias technical to improve the energy and activity of deposited particles, and enhance the properties of coating. It can deposit coatings on the surface of metal as well as non-metal.

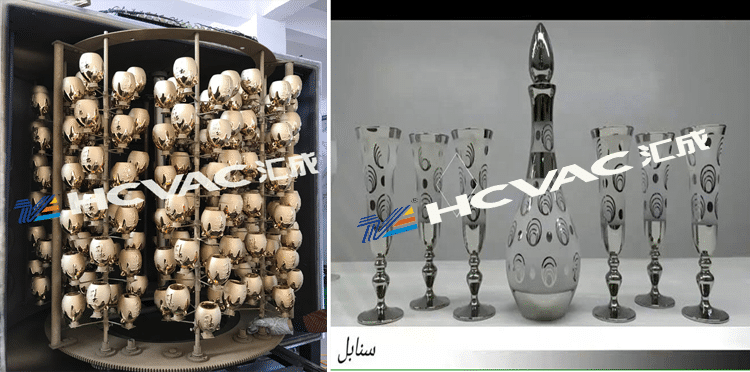

Applied industries: It is widely used in the glass products, watchband, watchcase, jewelry, mobile shell, hardware, tableware, etc. It can coat TiN, TiC, TiCN, TiAlN, CrN, Cu, Au, Al2O3 and other decorative films. It can get fineness and smooth film, good adhesion coating effect!

Color series:

Imitation gold series: TiN, ZrN, TiN+Au, ZrN+Au

Rose Gold Series: TiCN, TiAlN, TiCN+Au--Cu, TiAlN+Au, Cu

Silver white series: CrN, CrSiN, Zr (micro N)

Grey series: Ti, stainless steel (S.S), (S.S) N

Coffee color series: TiCN, TiAlCN, ZrC

Blue series: TiO, CrO, TiALN

Black Series: TiC, TiC+iC, TiCN, TiAlN, TiAlCN, Ti (C,O) and DLC

(It can coat all kinds of materials. We will design the size and configuration according to your requirements)

Easy to implement

To many people unfamiliar with the process, PVD coating technology seems complicated. However, with the right investments and a good support, it is easier than expected. HCVAC has developed a turnkey coating process that makes a PVD coating centre easy to implement. A complete coating process consists of several steps: Stripping (depending on the parts history); Pre-treatment; Quality control; Cleaning & drying; Fixturing & visual inspection; PVD coating; Quality control & thickness measurement and post-treatment (depending on the application). These steps are all available from one partner: HCVAC Technology, including mature technics and coatings.

We developed a complete after-sales system and effective service measures. Company now owns a professional after-sales service team with more than ten experienced engineers.

ISO 9001 standard to ensure the quality can meet the customers requirements.

Please feel free to contact us for further information!

Technical parameters:

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||

FAQs of HCVAC Glass Cup Bottle Golden Color PVD Vacuum Coating Machine Plant:

Q: What is the power consumption of the HCVAC Glass Cup Bottle Golden Color PVD Vacuum Coating Machine Plant?

A: The power consumption of the machine is 45-90KW.Q: What is the warranty period for this machine?

A: The machine comes with a one year warranty and lifetime maintenance.Q: What is the general use of this coating machine?

A: The machine is suitable for coating glass products, watchband, watchcase, jewelry, mobile shell, hardware, tableware, etc.Q: Does the machine have a humidification system?

A: Yes, the machine is equipped with a humidification system.Q: What are the different color options available for coating?

A: The machine can coat in gold, silver, rose gold, black, blue, and other colors.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

+91

Email

जांच भेजें

जांच भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें