Call us now : +8613316689188

HCVAC Plastic Aluminum Vacuum Metallizing Coating Machine

60000-200000 USD ($)/Set

Product Details:

- Product Type Coating Production Line

- Material Stainless Steel

- Type Industrial Coating Machine Metal Coating Machine

- Weight (kg) 5-8 Ton

- Computerized Yes

- Automatic Yes

- Control System PLC Control

- Click to View more

X

HCVAC Plastic Aluminum Vacuum Metallizing Coating Machine Price And Quantity

- 60000-200000 USD ($)/Set

- 1 Set

HCVAC Plastic Aluminum Vacuum Metallizing Coating Machine Product Specifications

- Coating

- Coating Production Line

- One year warranty, lifetime maintenance

- customized

- Stainless Steel

- Yes

- PLC Control

- 45-90KW

- Silver, Golden, Black, Rose Gold, Pink, Bronze, Coffee

- 380V

- Yes

- 5-8 Ton

- Industrial Coating Machine Metal Coating Machine

HCVAC Plastic Aluminum Vacuum Metallizing Coating Machine Trade Information

- FOB SHENZHEN

- Telegraphic Transfer (T/T) Letter of Credit (L/C)

- 60 Days

- Contact us for information regarding our sample policy

- wooden package

- Eastern Europe Western Europe Middle East Asia

- All India

- CE, ISO

Product Description

The high vacuum coating equipment adopts the resistance heating in the vacuum chamber, to melt and vaporize the metal wire (aluminum wire) cling to the resistance wire. The vaporized metal molecule deposit on the substrates, to gain the smooth film as well as high reflectivity. Thus the surface of the items can be decorated and beautified.

Characteristic: Reasonable structure, even film, good-quality film forming, quick pumping speed, the cycle of short, high efficiency and easy operation, low energy consumption and performance advantages of stability.

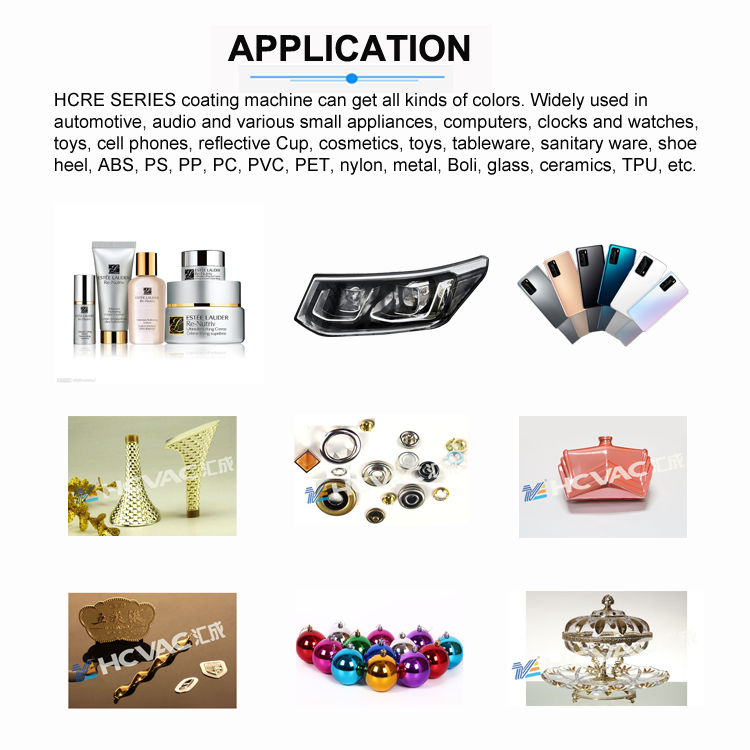

Widely used in automotive, audio and various small appliances, computers, clocks and watches, toys, cell phones, reflective Cup, cosmetics, toys, tableware, sanitary ware, shoe heel, ABS, PS, PP, PC, PVC, PET, nylon, metal, Boli, glass, ceramics, TPU, etc.

Electroplating effects: General electroplating-face, dumb-(semi-mute, all dumb), the electroplating process wrinkles, lampworking, raindrops, seven colors;

Coating Gold, silver, red, blue, green, purple, multi color, and so on.

The coating experts of your own company: Full set solution for the coating production.

HCVAC can help you to enter the PVD coating easily by our vacuum coating machine and full range service. We will provide with most suitable technology according to your requirements.

We will make the special coating solution for each customer; Combine the full set production technic to meet your requirements, to ensure high efficiency of production.

Easy to implement

To many people unfamiliar with the process, PVD coating technology seems complicated. However, with the right investments and a good support, it is easier than expected. HCVAC has developed a turnkey coating process that makes a PVD coating centre easy to implement. A complete coating process consists of several steps: Stripping (depending on the parts history); Pre-treatment; Quality control; Cleaning & drying; Fixturing & visual inspection; PVD coating; Quality control & thickness measurement and post-treatment (depending on the application). These steps are all available from one partner: HCVAC Technology, including mature technics and coatings.

We developed a complete after-sales system and effective service measures. Company now owns a professional after-sales service team with more than ten experienced engineers.

A special after-sales service hotline is set up to provide the customers with satisfactory problem solutions and technical support.

ISO 9001 standard to ensure the quality can meet the customers requirements.

Technical parameters:

|

Mode Dimension |

ZZ-1214 |

ZZ-1416 |

ZZ-1618 |

ZZ-1820 |

|

1200*1400mm |

1400*1600mm |

1600*1800mm |

1800*2000mm |

|

|

Film Type |

Semitransparent film, non-conducting film, gold, silver, red, blue, green, purple, seven color, etc. |

|||

|

Power source Type |

Thermal evaporation power, ion bombard power, RF power |

|||

|

Vacuum chamber structure |

Vertical double/single door, horizontal single door, pump system postposition |

|||

|

Ultimate vacuum |

8.0*10-4Pa |

|||

|

Vacuum system |

Diffusion pump +Roots pump +Mechanical pump +Holding pump |

|||

|

Pump time |

Pump from atmosphere to 5.0*10-2,6 minutes |

|||

|

Workpiece motion mode |

Public rotation/Frequency control |

|||

|

Control mode |

Manual/Automatic all-in-one mode, Touching screen+PLC |

|||

|

Remark |

We can design the dimension of the vacuum chamber according to customers demand. |

|||

FAQs of HCVAC Plastic Aluminum Vacuum Metallizing Coating Machine:

Q: What is the warranty for HCVAC Plastic Aluminum Vacuum Metallizing Coating Machine?

A: The machine comes with a one year warranty and lifetime maintenance.Q: What type of coating machine is HCVAC Plastic Aluminum Vacuum Metallizing Coating Machine?

A: It is an industrial metal coating machine.Q: Is HCVAC Plastic Aluminum Vacuum Metallizing Coating Machine computerized?

A: Yes, it is computerized.Q: What is the power consumption of HCVAC Plastic Aluminum Vacuum Metallizing Coating Machine?

A: The power consumption ranges from 45-90KW.Q: What is the control system of HCVAC Plastic Aluminum Vacuum Metallizing Coating Machine?

A: It has a PLC control system.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry